Общий каталог Mitsubishi 2020 - 2021 - страница 1222

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

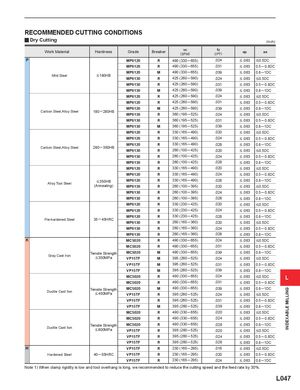

RECOMMENDED CUTTING CONDITIONS y Dry Cutting (inch) Work Material Hardness Grade Breaker vc(SFM) fz(IPT) ap ae P MP6120 R 490 (330 ─ 655) .024 < .063 <0.5DC MP6120 R 490 (330 ─ 655) .031 < .063 0.5 ─ 0.8DC MP6120 M 490 (330 ─ 655) .039 < .063 0.8 ─1DC Mild Steel <180HB MP6130 R 425 (260 ─ 590) .024 < .063 <0.5DC MP6130 R 425 (260 ─ 590) .031 < .063 0.5 ─ 0.8DC MP6130 M 425 (260 ─ 590) .039 < .063 0.8 ─1DC MP6120 R 425 (260 ─ 590) .024 < .063 <0.5DC MP6120 R 425 (260 ─ 590) .031 < .063 0.5 ─ 0.8DC Carbon Steel,Alloy Steel 180 ─ 280HB MP6120MP6130 M 425 (260 ─ 590)R360 (195 ─ 525).039.024 < .063 0.8 ─1DC< .063<0.5DC MP6130 R 360 (195 ─ 525) .031 < .063 0.5 ─ 0.8DC MP6130 M 360 (195 ─ 525) .039 < .063 0.8 ─1DC MP6120 R 330 (165 ─ 490) .020 < .063 <0.5DC MP6120 R 330 (165 ─ 490) .024 < .063 0.5 ─ 0.8DC Carbon Steel,Alloy Steel 280 ─ 350HB MP6120MP6130 R 330 (165 ─ 490) .028R260 (100 ─ 425).020< .0630.8 ─1DC< .063<0.5DC MP6130 R 260 (100 ─ 425) .024 < .063 0.5 ─ 0.8DC MP6130 R 260 (100 ─ 425) .028 < .063 0.8 ─1DC MP6120 R 330 (165 ─ 490) .020 < .063 <0.5DC MP6120 R 330 (165 ─ 490) .024 < .063 0.5 ─ 0.8DC Alloy Tool Steel < 350HB MP6120 R 330 (165 ─ 490) .028 < .063 0.8 ─1DC(Annealing)MP6130R260 (100 ─ 395).020< .063<0.5DC MP6130 R 260 (100 ─ 395) .024 < .063 0.5 ─ 0.8DC MP6130 R 260 (100 ─ 395) .028 < .063 0.8 ─1DC MP6120 R 330 (230 ─ 425) .020 < .063 <0.5DC MP6120 R 330 (230 ─ 425) .024 < .063 0.5 ─ 0.8DC Pre-hardened Steel 35 ─ 45HRC MP6120MP6130 R 330 (230 ─ 425) .028R260 (165 ─ 360).020< .0630.8 ─1DC< .063<0.5DC MP6130 R 260 (165 ─ 360) .024 < .063 0.5 ─ 0.8DC MP6130 R 260 (165 ─ 360) .028 < .063 0.8 ─1DC K MC5020 R 490 (330 ─ 655) .024 < .063 <0.5DC MC5020 R 490 (330 ─ 655) .031 < .063 0.5 ─ 0.8DC Gray Cast Iron Tensile Strength MC5020 M 490 (330 ─ 655) .039 < .063 0.8 ─1DC< 350MPaVP15TFM395 (260 ─ 525).024< .063<0.5DC VP15TF M 395 (260 ─ 525) .031 < .063 0.5 ─ 0.8DC VP15TF M 395 (260 ─ 525) .039 < .063 0.8 ─1DC MC5020 R 490 (330 ─ 655) .024 < .063 <0.5DC L MC5020 R 490 (330 ─ 655) .031 < .063 0.5 ─ 0.8DC Ductile Cast Ilon Tensile Strength MC5020 M 490 (330 ─ 655) .039< 450MPaVP15TFR395 (260 ─ 525).024< .0630.8 ─1DC< .063<0.5DC VP15TF R 395 (260 ─ 525) .031 < .063 0.5 ─ 0.8DC VP15TF M 395 (260 ─ 525) .039 < .063 0.8 ─1DC MC5020 R 490 (330 ─ 655) .020 < .063 <0.5DC MC5020 R 490 (330 ─ 655) .024 < .063 0.5 ─ 0.8DC Ductile Cast Ilon Tensile Strength MC5020 R 490 (330 ─ 655) .028< 800MPaVP15TFR395 (260 ─ 525).020< .0630.8 ─1DC< .063<0.5DC VP15TF R 395 (260 ─ 525) .024 < .063 0.5 ─ 0.8DC VP15TF R 395 (260 ─ 525) .028 < .063 0.8 ─1DC H VP15TF R 230 (165 ─ 295) .016 < .063 <0.5DC Hardened Steel 40 ─ 55HRC VP15TF R 230 (165 ─ 295) .020 < .063 0.5 ─ 0.8DC VP15TF R 230 (165 ─ 295) .024 < .063 0.8 ─1DC Note 1) When clamp rigidity is low and tool overhang is long, we recommended to reduce the cutting speed and the feed rate by 30%. L047 INDEXABLE MILLING