Общий каталог Mitsubishi 2020 - 2021 - страница 1189

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

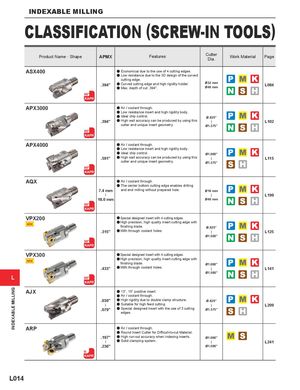

INDEXABLE MILLING CLASSIFICATION (SCREW-IN TOOLS) Product Name · Shape APMX Features CutterDia. Work Material Page ASX400 a Economical due to the use of 4 cutting edges. a Low resistance due to the 3D design of the curved cutting edge. .394" a Curved cutting edge and high rigidity holder.a Max. depth of cut .394".Ø32 mmØ40 mm L084 90° KAPR APX3000 a Air / coolant through. a Low resistance insert and high rigidity body. a Ideal chip control. Ø.625" .394" a High wall accuracy can be produced by using this | L102 cutter and unique insert geometry. Ø1.375" 90° KAPR APX4000 a Air / coolant through. a Low resistance insert and high rigidity body. a Ideal chip control. Ø1.000" .591" a High wall accuracy can be produced by using this | L115 cutter and unique insert geometry. Ø1.375" 90° KAPR AQX a Air / coolant through. a The center bottom cutting edge enables drilling 7.4 mm and end milling without prepared hole. Ø16 mm | | L199 18.0 mm Ø40 mm 90° KAPR VPX200 a Special designed insert with 4 cutting edges. a High precision, high quality insert cutting edge with finishing blade. Ø.625" .315" a With through coolant holes. | L125 Ø1.500" 90° KAPR VPX300 a Special designed insert with 4 cutting edges. a High precision, high quality insert cutting edge with finishing blade. Ø1.000" .433" a With through coolant holes. | L141 Ø1.500" L 90° KAPR AJX a 13°, 15° positive insert. a Air / coolant through. .039" a High rigidity due to double clamp structure. Ø.625" | a Suitable for high feed cutting. | L209 .079" a Special designed insert with the use of 3 cutting Ø1.375" edges. ARP a Air / coolant through. a Round Insert Cutter for Difficult-to-cut Material. .197" a High run-out accuracy when indexing inserts. Ø1.000" | a Solid clamping system. | L241 .236" Ø1.500" R KAPR L014 INDEXABLE MILLING