Общий каталог Mitsubishi 2020 - 2021 - страница 1162

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

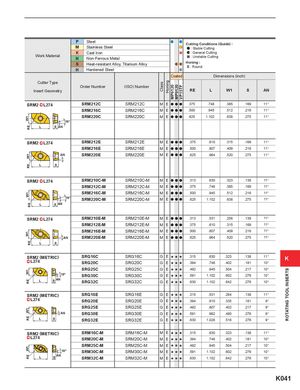

W1REW1REW1REW1REW1REW1REW1RE Class Honing MP6120 MP9120 VP15TF ROTATING TOOL INSERTS P Steel Cutting Conditions (Guide) : M Stainless Steel : Stable Cutting Work Material K Cast IronNNon-Ferrous Metal : General Cutting: Unstable Cutting S Heat-resistant Alloy, Titanium AlloyHHardened Steel Honing :E : Round Coated Dimensions (inch) Cutter Type Order Number (ISO) Number Insert Geometry RE L W1 S AN SRM2 ^L274 SRM212C SRM212C M E a a a .375 .748 .385 .169 11° SRM216C SRM216C M E a a a .500 .945 .512 .216 11° SRM220C SRM220C M E a a a .625 1.102 .638 .275 11° 18° L S AN SRM2 ^L274 SRM212E SRM212E M E a a a .375 .610 .315 .169 11° SRM216E SRM216E M E a a a .500 .807 .409 .216 11° AN SRM220E SRM220E M E a a a .625 .964 .520 .275 11° L S SRM2 ^L274 SRM210C-M SRM210C-M M E a a a .313 .630 .323 .138 11° SRM212C-M SRM212C-M M E a a a .375 .748 .385 .169 11° SRM216C-M SRM216C-M M E a a a .500 .945 .512 .216 11° 18° SRM220C-M SRM220C-M M E a a a .625 1.102 .638 .275 11° L S AN SRM2 ^L274 SRM210E-M SRM210E-M M E a a a .313 .531 .258 .138 11° SRM212E-M SRM212E-M M E a a a .375 .610 .315 .169 11° SRM216E-M SRM216E-M M E a a a .500 .807 .409 .216 11° AN SRM220E-M SRM220E-M M E a a a .625 .964 .520 .275 11° L S SRM2 (METRIC) SRG16C^L274SRG20C SRG16C G E sss .315 .630 .323 .138 11° KSRG20CGEsss.394.748.402.18110° SRG25C SRG25C G E sss .492 .945 .504 .217 10° 18° SRG30C SRG30C G E sss .591 1.102 .602 .276 10° L S AN SRG32C SRG32C G E sss .630 1.102 .642 .276 10° SRM2 (METRIC) SRG16E SRG16E G E sss .315 .531 .264 .138 11° ^L274 SRG20E SRG20E G E sss .394 .610 .335 .181 9° SRG25E SRG25E G E sss .492 .807 .402 .217 9° AN SRG30E SRG30E G E sss .591 .992 .480 .276 9° L S SRG32E SRG32E G E sss .630 1.028 .516 .276 9° SRM2 (METRIC) SRM16C-M SRM16C-M M E sss .315 .630 .323 .138 11° ^L274 SRM20C-M SRM20C-M M E sss .394 .748 .402 .181 10° SRM25C-M SRM25C-M M E sss .492 .945 .504 .217 10° 18° SRM30C-M SRM30C-M M E sss .591 1.102 .602 .276 10° L S AN SRM32C-M SRM32C-M M E sss .630 1.102 .642 .276 10° K041