Общий каталог Mitsubishi 2020 - 2021 - страница 1130

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

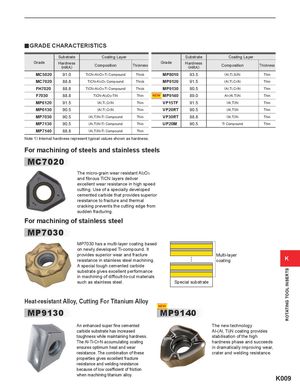

y GRADE CHARACTERISTICS Substrate Coating Layer Substrate Coating Layer Grade Hardness(HRA) Composition Thickness Grade Hardness(HRA) Composition Thickness MC5020 91.0 TiCN-AI2O3-Ti Compound Thick MP8010 93.5 (Al,Ti,Si)N Thin MC7020 88.8 TiCN-AI2O3 Compound Thick MP9120 91.5 (Al,Ti,Cr)N Thin FH7020 88.8 TiCN-AI2O3-Ti Compound Thick MP9130 90.5 (Al,Ti,Cr)N Thin F7030 88.8 TiCN-Al2O3-TiN Thin MP9140 89.0 Al-(Al,Ti)N Thin MP6120 91.5 (Al,Ti,Cr)N Thin VP15TF 91.5 (Al,Ti)N Thin MP6130 90.5 (Al,Ti,Cr)N Thin VP20RT 90.5 (Al,Ti)N Thin MP7030 90.5 (Al,Ti)N-Ti Compound Thin VP30RT 88.8 (Al,Ti)N Thin MP7130 90.5 (Al,Ti)N-Ti Compound Thin UP20M 90.5 Ti Compound Thin MP7140 88.8 (Al,Ti)N-Ti Compound Thin Note 1) Internal hardness represent typical values shown as hardness. For machining of steels and stainless steels MC7020 The micro-grain wear resistant Al2O3 and fibrous TiCN layers deliver excellent wear resistance in high speed cutting. Use of a specially developed cemented carbide that provides superior resistance to fracture and thermal cracking prevents the cutting edge from sudden fracturing. For machining of stainless steel MP7030 MP7030 has a multi-layer coating based on newly developed Ti-compound. It provides superior wear and fractureresistance in stainless steel machining. Multi-layercoating K A special tough cemented carbide substrate gives excellent performance in machining of difficult-to-cut materials such as stainless steel. Special substrate Heat-resistant Alloy, Cutting For Titanium Alloy MP9130 MP9140 An enhanced super fine cemented The new technology carbide substrate has increased Al-(Al, Ti)N coating provides toughness while maintaining hardness. stabilisation of the high The Al-Ti-Cr-N accumulating coating hardness phase and succeeds ensures optimum heat and wear in dramatically improving wear, resistance. The combination of these crater and welding resistance. properties gives excellent fracture resistance and welding resistance because of low coefficient of friction when machining titanium alloy. K009 ROTATING TOOL INSERTS