Общий каталог Mitsubishi 2020 - 2021 - страница 1129

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

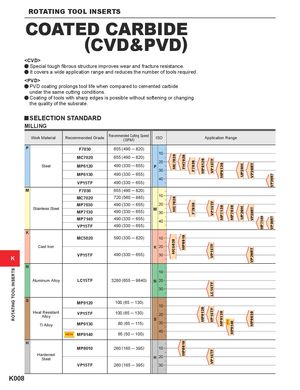

ROTATING TOOL INSERTS

MC7020MC7020MC5020

FH7020MP8010MP8010

F7030F7030

MP6120MP9120

VP15TFVP15TFVP15TFLC15TFVP15TFVP15TF

MP6130MP7130MP9130

MP7030MP9140

UP20MUP20M

VP20RTVP20RTVP20RTMP9030

MP7140

VP30RTVP30RT

ROTATING TOOL INSERTS

COATED CARBIDE

(CVD&PVD)