Общий каталог Mitsubishi 2020 - 2021 - страница 1061

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

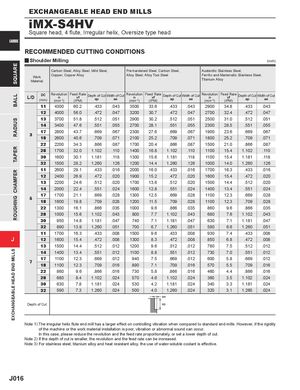

SQUAREBALLRADIUSTAPERCHAMFERROUGHINGEXCHANGEABLE HEAD END MILLS EXCHANGEABLE HEAD END MILLS iMX-S4HV Square head, 4 flute, Irregular helix, Oversize type head CARBIDE RECOMMENDED CUTTING CONDITIONS y Shoulder Milling (inch) Carbon Steel, Alloy Steel, Mild Steel, Pre-hardened Steel, Carbon Steel, Austenitic Stainless Steel, Work Copper, Copper AlloyMaterial Alloy Steel, Alloy Tool Steel Ferritic and Martensitic Stainless Steel,Titanium Alloy L/D DC(mm)Revolutionn(min-1)Feed Rate vf (IPM) Depth of Cut Width of Cut ap aeRevolutionn(min-1)Feed Rate vf (IPM) Depth of Cut Width of Cut ap aeRevolutionn(min-1)Feed Rate vf (IPM) Depth of Cut Width of Cut ap ae 11 4300 60.2 .433 .043 3500 33.6 .433 .043 2900 34.8 .433 .043 12 4000 56.0 .472 .047 3200 30.7 .472 .047 2700 32.4 .472 .047 13 3700 51.8 .512 .051 2900 30.2 .512 .051 2500 31.0 .512 .051 14 3400 47.6 .551 .055 2700 28.1 .551 .055 2300 28.5 .551 .055 3 1718 28002600 43.740.6 .669 .067 2300 27.6.709.071210025.2.669 .067 1900 23.6.709.071180025.2.669 .067.709.071 22 2200 34.3 .866 .087 1700 20.4 .866 .087 1500 21.0 .866 .087 28 1700 32.0 1.102 .110 1400 16.8 1.102 .110 1100 15.4 1.102 .110 30 1600 30.1 1.181 .118 1300 15.6 1.181 .118 1100 15.4 1.181 .118 32 1500 28.2 1.260 .126 1200 14.4 1.260 .126 1000 14.0 1.260 .126 11 2600 29.1 .433 .016 2000 16.0 .433 .016 1700 16.3 .433 .016 12 2400 26.9 .472 .020 1900 15.2 .472 .020 1600 15.4 .472 .020 13 2200 24.6 .512 .020 1700 13.6 .512 .020 1500 14.4 .512 .020 14 2000 22.4 .551 .024 1600 12.8 .551 .024 1400 13.4 .551 .024 5 1718 17001600 21.119.8 .669 .028 1300 12.5.709.028120011.5.669 .028 1100 12.3.709.028110012.3.669 .028.709.028 22 1300 16.1 .866 .035 1000 9.6 .866 .035 860 9.6 .866 .035 28 1000 15.6 1.102 .043 800 7.7 1.102 .043 680 7.6 1.102 .043 30 950 14.8 1.181 .047 740 7.1 1.181 .047 630 7.1 1.181 .047 32 890 13.9 1.260 .051 700 6.7 1.260 .051 590 6.6 1.260 .051 11 1700 16.3 .433 .008 1500 9.6 .433 .008 930 7.4 .433 .008 J 12 1600 15.4 .472 .008 1300 8.3 .472 .008 850 6.8 .472 .008 13 1500 14.4 .512 .012 1200 9.6 .512 .012 780 7.5 .512 .012 14 1400 13.4 .551 .012 1100 8.8 .551 .012 730 7.0 .551 .012 7 1718 11001100 12.312.3 .669 .012.709.016 940890 7.57.1 .669 .012.709.016 600570 5.85.5 .669 .012.709.016 22 860 9.6 .866 .016 730 5.8 .866 .016 460 4.4 .866 .016 28 680 8.4 1.102 .024 570 4.6 1.102 .024 360 3.5 1.102 .024 30 630 7.8 1.181 .024 530 4.2 1.181 .024 340 3.3 1.181 .024 32 590 7.3 1.260 .024 500 4.0 1.260 .024 320 3.1 1.260 .024 ae Depth of Cut ap Note 1) The irregular helix flute end mill has a larger effect on controlling vibration when compared to standard end mills. However, if the rigidity of the machine or the work material installation is poor, vibration or abnormal sound can occur. In this case, please reduce the revolution and the feed rate proportionately, or set a lower depth of cut. Note 2) If the depth of cut is smaller, the revolution and the feed rate can be increased. Note 3) For stainless steel, titanium alloy and heat resistant alloy, the use of water-soluble coolant is effective. J016