Общий каталог Mitsubishi 2020 - 2021 - страница 1030

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

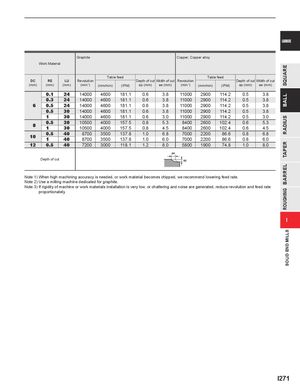

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE Graphite Copper, Copper alloy Work Material Table feed Table feed DC RE LU Revolution Depth of cut Width of cut Revolution Depth of cut Width of cut (mm) (mm) (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) 0.1 24 14000 4600 181.1 0.6 3.8 11000 2900 114.2 0.5 3.8 0.3 24 14000 4600 181.1 0.6 3.8 11000 2900 114.2 0.5 3.8 6 0.5 24 14000 4600 181.1 0.6 3.8 11000 2900 114.2 0.5 3.8 0.5 30 14000 4600 181.1 0.6 3.8 11000 2900 114.2 0.5 3.8 1 30 14000 4600 181.1 0.6 3.0 11000 2900 114.2 0.5 3.0 8 0.5 30 10500 4000 157.5130105004000157.50.80.85.34.5 8400 2600 102.4 0.684002600102.40.65.34.5 10 0.51 4040 8700 3500 137.8 1.087003500137.81.06.86.0 7000 2200 86.6 0.87000220086.60.86.86.0 12 0.5 40 7200 3000 118.1 1.2 8.0 5800 1900 74.8 1.0 8.0 ae Depth of cut ap Note 1) When high machining accuracy is needed, or work material becomes chipped, we recommend lowering feed rate. Note 2) Use a milling machine dedicated for graphite. Note 3) If rigidity of machine or work materials installation is very low, or chattering and noise are generated, reduce revolution and feed rate proportionately. I I271