Общий каталог Mitsubishi 2020 - 2021 - страница 1029

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

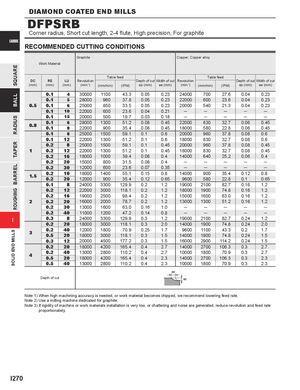

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS DIAMOND COATED END MILLS DFPSRB Corner radius, Short cut length, 2-4 flute, High precision, For graphite CARBIDE RECOMMENDED CUTTING CONDITIONS Graphite Copper, Copper alloy Work Material Table feed Table feed DC RE LU Revolution Depth of cut Width of cut Revolution Depth of cut Width of cut (mm) (mm) (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) 0.1 4 30000 1100 43.3 0.05 0.23 24000 700 27.6 0.04 0.23 0.1 5 28000 960 37.8 0.05 0.23 22000 600 23.6 0.04 0.23 0.5 0.1 6 25000 850 33.5 0.05 0.23 20000 540 21.3 0.04 0.23 0.1 10 22000 600 23.6 0.04 0.21 ─ ─ ─ ─ ─ 0.1 15 20000 500 19.7 0.03 0.18 ─ ─ ─ ─ ─ 0.8 0.10.1 6 28000 1300 51.2 0.08 0.45 22000 830 32.7 0.06 0.4582200090035.40.080.451800058022.80.060.45 0.1 8 25000 1500 59.1 0.1 0.6 20000 960 37.8 0.08 0.6 0.1 12 22000 1300 51.2 0.1 0.6 18000 830 32.7 0.08 0.6 0.2 8 25000 1500 59.1 0.1 0.45 20000 960 37.8 0.08 0.45 1 0.2 12 22000 1300 51.2 0.1 0.45 18000 830 32.7 0.08 0.45 0.2 16 18000 1000 39.4 0.08 0.4 14000 640 25.2 0.06 0.4 0.2 20 15000 800 31.5 0.08 0.4 ─ ─ ─ ─ ─ 0.2 30 12000 600 23.6 0.07 0.35 ─ ─ ─ ─ ─ 1.5 0.20.2 1020 18000 14001200090055.1 0.1535.40.120.8 14000 9000.65960058035.4 0.1222.80.1 0.80.65 0.1 8 24000 3300 129.9 0.2 1.2 19000 2100 82.7 0.16 1.2 0.2 12 22000 3000 118.1 0.2 1.2 18000 1900 74.8 0.16 1.2 0.2 16 19000 2500 98.4 0.2 1.2 15000 1600 63.0 0.16 1.2 2 0.2 20 16000 2000 78.7 0.2 1.2 13000 1300 51.2 0.16 1.2 0.2 30 13000 1600 63.0 0.16 1.0 ─ ─ ─ ─ ─ 0.2 40 11000 1200 47.2 0.14 0.8 ─ ─ ─ ─ ─ I 0.3 8 24000 3300 129.9 0.3 1.2 19000 2100 82.7 0.24 1.2 0.2 20 18000 3000 118.1 0.3 2.0 14000 1900 74.8 0.24 2.0 3 0.2 40 12000 1800 70.9 0.25 1.7 9600 1100 43.3 0.2 1.70.520180003000118.10.31.514000190074.80.241.5 0.3 12 20000 4500 177.2 0.3 1.5 16000 2900 114.2 0.24 1.5 0.2 20 18000 4200 165.4 0.4 2.7 14000 2700 106.3 0.3 2.7 4 0.2 40 13000 2800 110.2 0.40.520180004200165.40.42.710000 1800 70.9 0.32.3140002700106.30.32.72.3 0.5 40 13000 2800 110.2 0.4 2.3 10000 1800 70.9 0.3 2.3 ae Depth of cut ap Note 1) When high machining accuracy is needed, or work material becomes chipped, we recommend lowering feed rate. Note 2) Use a milling machine dedicated for graphite. Note 3) If rigidity of machine or work materials installation is very low, or chattering and noise are generated, reduce revolution and feed rate proportionately. I270