Каталог Iscar токарный инструмент 2017 - страница 102

Навигация

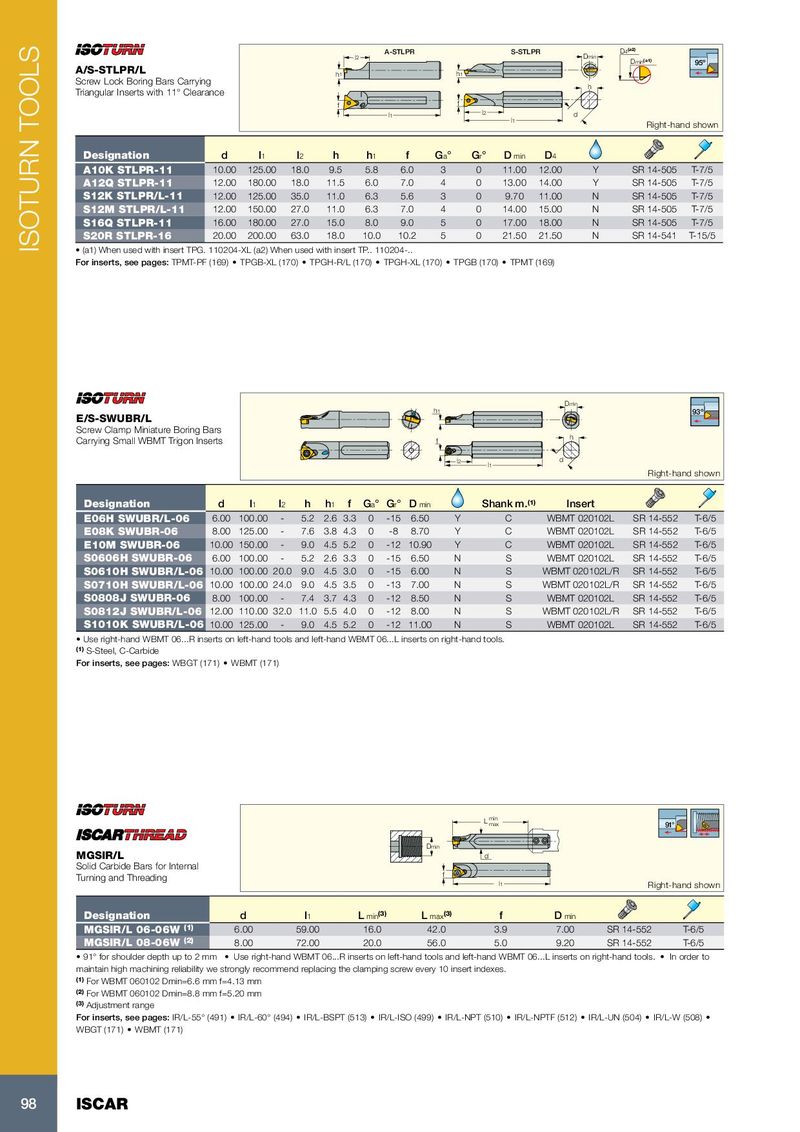

A-STLPR S-STLPR D4 (a2) l 2 Dmin Dmin (a1) 95º A/S-STLPR/L h 1 h 1 Screw Lock Boring Bars Carrying h Triangular Inserts with 11° Clearance f f l 1 l 2 d l 1 Right-hand shown Designation d l 1 l 2 h h 1 f G a ° G r ° D min D 4 A10K STLPR-11 10.00 125.00 18.0 9.5 5.8 6.0 3 0 11.00 12.00 Y SR 14-505 T-7/5 A12Q STLPR-11 12.00 180.00 18.0 11.5 6.0 7.0 4 0 13.00 14.00 Y SR 14-505 T-7/5 S12K STLPR/L-11 12.00 125.00 35.0 11.0 6.3 5.6 3 0 9.70 11.00 N SR 14-505 T-7/5 S12M STLPR/L-11 12.00 150.00 27.0 11.0 6.3 7.0 4 0 14.00 15.00 N SR 14-505 T-7/5 S16Q STLPR-11 16.00 180.00 27.0 15.0 8.0 9.0 5 0 17.00 18.00 N SR 14-505 T-7/5 S20R STLPR-16 20.00 200.00 63.0 18.0 10.0 10.2 5 0 21.50 21.50 N SR 14-541 T-15/5 ISOTURN TOOLS • (a1) When used with insert TPG. 110204-XL (a2) When used with insert TP.. 110204-.. For inserts, see pages: TPMT-PF (169) • TPGB-XL (170) • TPGH-R/L (170) • TPGH-XL (170) • TPGB (170) • TPMT (169) Dmin h 1 93º E/S-SWUBR/L Screw Clamp Miniature Boring Bars h Carrying Small WBMT Trigon Inserts f l 2 d l 1 Right-hand shown Designation d l 1 l 2 h h 1 f G a ° G r ° D min Shank m. (1) Insert E06H SWUBR/L-06 6.00 100.00 - 5.2 2.6 3.3 0 -15 6.50 Y C WBMT 020102L SR 14-552 T-6/5 E08K SWUBR-06 8.00 125.00 - 7.6 3.8 4.3 0 -8 8.70 Y C WBMT 020102L SR 14-552 T-6/5 E10M SWUBR-06 10.00 150.00 - 9.0 4.5 5.2 0 -12 10.90 Y C WBMT 020102L SR 14-552 T-6/5 S0606H SWUBR-06 6.00 100.00 - 5.2 2.6 3.3 0 -15 6.50 N S WBMT 020102L SR 14-552 T-6/5 S0610H SWUBR/L-06 10.00 100.00 20.0 9.0 4.5 3.0 0 -15 6.00 N S WBMT 020102L/R SR 14-552 T-6/5 S0710H SWUBR/L-06 10.00 100.00 24.0 9.0 4.5 3.5 0 -13 7.00 N S WBMT 020102L/R SR 14-552 T-6/5 S0808J SWUBR-06 8.00 100.00 - 7.4 3.7 4.3 0 -12 8.50 N S WBMT 020102L SR 14-552 T-6/5 S0812J SWUBR/L-06 12.00 110.00 32.0 11.0 5.5 4.0 0 -12 8.00 N S WBMT 020102L/R SR 14-552 T-6/5 S1010K SWUBR/L-06 10.00 125.00 - 9.0 4.5 5.2 0 -12 11.00 N S WBMT 020102L SR 14-552 T-6/5 • Use right-hand WBMT 06...R inserts on left-hand tools and left-hand WBMT 06...L inserts on right-hand tools. (1) S-Steel, C-Carbide For inserts, see pages: WBGT (171) • WBMT (171) L min max 91° Dmin MGSIR/L d Solid Carbide Bars for Internal Turning and Threading f l1 Right-hand shown Designation d l 1 L min (3) L max (3) f D min MGSIR/L 06-06W (1) 6.00 59.00 16.0 42.0 3.9 7.00 SR 14-552 T-6/5 MGSIR/L 08-06W (2) 8.00 72.00 20.0 56.0 5.0 9.20 SR 14-552 T-6/5 • 91° for shoulder depth up to 2 mm • Use right-hand WBMT 06...R inserts on left-hand tools and left-hand WBMT 06...L inserts on right-hand tools. • In order to maintain high machining reliability we strongly recommend replacing the clamping screw every 10 insert indexes. (1) For WBMT 060102 Dmin=6.6 mm f=4.13 mm (2) For WBMT 060102 Dmin=8.8 mm f=5.20 mm (3) Adjustment range For inserts, see pages: IR/L-55° (491) • IR/L-60° (494) • IR/L-BSPT (513) • IR/L-ISO (499) • IR/L-NPT (510) • IR/L-NPTF (512) • IR/L-UN (504) • IR/L-W (508) • WBGT (171) • WBMT (171) 98 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017