Каталог Iscar токарные пластины ISO 2022 - страница 68

Навигация

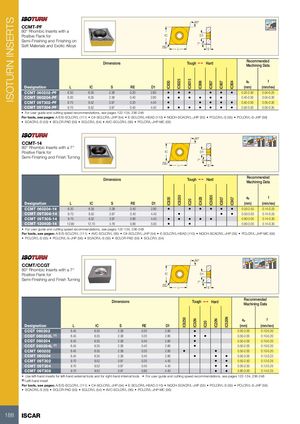

ISOTURN INSERTS IC830IC830 IC6025IC8250 IC8250 IC6015IC20 IC30N IC806IC428 IC20 IC807IC5005 IC20N IC907IC807 IC520N IC804IC907 80° CCMT-PF 95º 80° Rhombic Inserts with a Positive Flank for IC D1 Semi-Finishing and Finishing on Soft Materials and Exotic Alloys 7°RE L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) CCMT 060202-PF 6.30 6.35 2.38 0.20 2.80 • • • • • • 0.20-2.50 0.04-0.25 CCMT 060204-PF 6.30 6.35 2.38 0.40 2.80 • • • • • • 0.40-2.50 0.04-0.30 CCMT 09T302-PF 9.70 9.52 3.97 0.20 4.40 • • • • • 0.50-3.00 0.05-0.30 CCMT 09T304-PF 9.70 9.52 3.97 0.40 4.40 • • • • • • • 0.50-3.50 0.05-0.35 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E/S-SCLCR/L (111) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • NQCH-SCACR/L-JHP (55) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56) • SCACR/L-S (55) • SCLCR-PAD (55) • SCLCR/L (54) • AVC-SCLCR/L (95) • PCLCR/L-JHP-MC (56) 80° 99° 95º CCMT-14 95º 91° 95º 80° Rhombic Inserts with a 7° Positive Flank for IC D1 Semi-Finishing and Finish Turning 7° RE L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) CCMT 060204-14 6.30 6.35 2.38 0.40 2.80 • • • • • • 0.50-2.50 0.14-0.25 CCMT 09T304-14 9.70 9.52 3.97 0.40 4.40 • • • 0.50-3.00 0.14-0.25 CCMT 09T308-14 9.70 9.52 3.97 0.80 4.40 • • • • • 0.80-3.00 0.14-0.30 CCMT 120408-14 12.90 12.70 4.76 0.80 5.50 • • 0.80-3.00 0.14-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E/S-SCLCR/L (111) • AVC-SCLCR/L (95) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • NQCH-SCACR/L-JHP (55) • PCLCR/L-JHP-MC (56) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56) • SCACR/L-S (55) • SCLCR-PAD (55) • SCLCR/L (54) 80° 95º 99° CCMT/CCGT 95º95º 91° 80° Rhombic Inserts with a 7° Positive Flank for IC D1 Semi-Finishing and Finish Turning 7° RE L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) CCGT 060202 6.45 6.35 2.38 0.20 2.80 • 0.50-2.00 0.10-0.20 CCGT 060202L (1) 6.45 6.35 2.38 0.20 2.80 • • 0.50-2.00 0.10-0.20 CCGT 060204 6.45 6.35 2.38 0.40 2.80 • 0.50-2.00 0.10-0.20 CCGT 060204L (1) 6.45 6.35 2.38 0.40 2.80 • 0.50-2.00 0.10-0.20 CCMT 060202 6.45 6.35 2.38 0.20 2.80 • • 0.50-2.00 0.10-0.20 CCMT 060204 6.45 6.35 2.38 0.40 2.80 • • • 0.50-2.00 0.12-0.22 CCMT 09T302 9.70 9.52 3.97 0.20 4.40 • • 0.50-2.50 0.12-0.25 CCMT 09T304 9.70 9.52 3.97 0.40 4.40 • • 0.50-2.50 0.12-0.25 CCMT 09T308 9.70 9.52 3.97 0.80 4.40 • • 0.80-3.00 0.14-0.25 • Use left-hand inserts for left-hand external tools and for right-hand internal tools • For user guide and cutting speed recommendations, see pages 122-134, 236-248 (1) Left-hand insert For tools, see pages: A/E/S-SCLCR/L (111) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • NQCH-SCACR/L-JHP (55) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56) • SCACR/L-S (55) • SCLCR-PAD (55) • SCLCR/L (54) • AVC-SCLCR/L (95) • PCLCR/L-JHP-MC (56) 188 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022