Каталог Iscar токарные пластины ISO 2022 - страница 12

Навигация

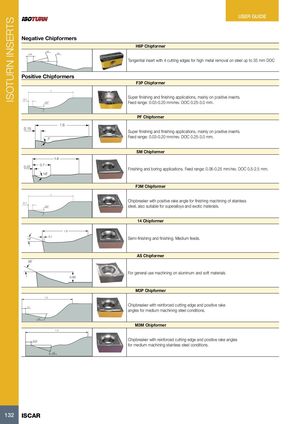

ISOTURN INSERTS USER GUIDE Negative Chipformers H6P Chipformer 15o 0.31 14o Tangential insert with 4 cutting edges for high metal removal on steel up to 35 mm DOC Positive Chipformers F3P Chipformer 1 Super finishing and finishing applications, mainly on positive inserts. 0.1 20° Feed range: 0.03-0.20 mm/rev. DOC 0.25-3.0 mm. PF Chipformer 1.6 0.15 Super finishing and finishing applications, mainly on positive inserts. 7˚ Feed range: 0.03-0.20 mm/rev. DOC 0.25-3.0 mm. SM Chipformer 1.8 0.07 0.7 Finishing and boring applications. Feed range: 0.06-0.25 mm/rev. DOC 0.5-2.5 mm. 18˚ F3M Chipformer 1 Chipbreaker with positive rake angle for finishing machining of stainless 0.1 20° steel, also suitable for superalloys and exotic materials. 14 Chipformer 1.5 0.119˚ Semi-finishing and finishing. Medium feeds. AS Chipformer 26˚ For general use machining on aluminum and soft materials. 0.65 M3P Chipformer 1.3 Chipbreaker with reinforced cutting edge and positive rake 0.1 angles for medium machining steel conditions. 12o M3M Chipformer 1.3 0.12 Chipbreaker with reinforced cutting edge and positive rake angles for medium machining stainless steel conditions. 19o 132 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022