Каталог Iscar токарные пластины ISO 2022 - страница 10

Навигация

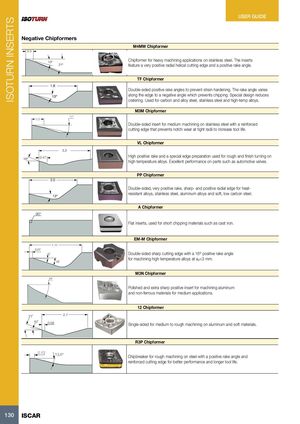

ISOTURN INSERTS USER GUIDE Negative Chipformers M4MW Chipformer 0.3 13º Chipformer for heavy machining applications on stainless steel. The inserts 21º feature a very positive radial helical cutting edge and a positive rake angle. TF Chipformer Double-sided positive rake angles to prevent strain hardening. The rake angle varies along the edge to a negative angle which prevents chipping. Special design reduces cratering. Used for carbon and alloy steel, stainless steel and high-temp alloys. M3M Chipformer 11° 0.2 Double-sided insert for medium machining on stainless steel with a reinforced cutting edge that prevents notch wear at tight radii to increase tool life. VL Chipformer 3.3 16° 0.47 High positive rake and a special edge preparation used for rough and finish turning onhigh temperature alloys. Excellent performance on parts such as automotive valves. PP Chipformer Double-sided, very positive rake, sharp- and positive radial edge for heat- resistant alloys, stainless steel, aluminum alloys and soft, low carbon steel. A Chipformer 90° Flat inserts, used for short chipping materials such as cast iron. EM-M Chipformer 1.11 0.07 5˚ Double-sided sharp cutting edge with a 16º positive rake angle 16˚ for machining high temperature alloys at ap<3 mm. M3N Chipformer 24° Polished and extra sharp positive insert for machining aluminum and non-ferrous materials for medium applications. 12 Chipformer 21˚ 2.7 10˚ 0.08 Single-sided for medium to rough machining on aluminum and soft materials. R3P Chipformer 0.12 13.5° Chipbreaker for rough machining on steel with a positive rake angle and reinforced cutting edge for better performance and longer tool life. 130 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022