Каталог Iscar расточные системы 2022 - страница 77

Навигация

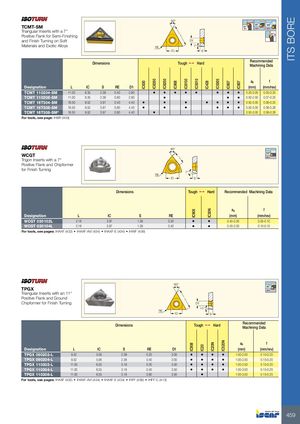

IC830 IC8350 IC8250 IC908 IC8150 IC5010IC908IC908 IC20 IC428IC30N IC20N IC5005 IC520N IC807 IC907 ITS BORE 60° TCMT-SM 91º 91º 95º Triangular Inserts with a 7° Positive Flank for Semi-Finishing L 91º and Finish Turning on Soft D1 Materials and Exotic Alloys RE 7° IC S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) TCMT 110204-SM 11.00 6.35 2.38 0.40 2.80 • • • • • • • • 0.20-3.00 0.05-0.25 TCMT 110208-SM 11.00 6.35 2.38 0.80 2.80 • • • 0.50-2.50 0.07-0.25 TCMT 16T304-SM 16.50 9.52 3.97 0.40 4.40 • • • • • • • 0.50-3.00 0.06-0.25 TCMT 16T308-SM 16.50 9.52 3.97 0.80 4.40 • • • • • • 0.50-3.00 0.08-0.28 TCMT 16T308-SM* 16.50 9.52 3.97 0.80 4.40 • 0.50-3.00 0.08-0.28 For tools, see page: IHBR (409) 80° WCGTTrigon Inserts with a 7° 93ºL Positive Flank and Chipformer for Finish Turning 7° RE IC S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) WCGT 020102L 2.18 3.97 1.59 0.20 • • 0.40-2.00 0.05-0.10 WCGT 020104L 2.18 3.97 1.59 0.40 • • 0.40-2.00 0.10-0.15 For tools, see pages: IHAXF (432) • IHAXF-AVI (434) • IHAXF-E (434) • IHWF (436) 60° TPGX 91º Triangular Inserts with an 11° Positive Flank and Ground L Chipformer for Finish Turning D1 11° RE IC S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) TPGX 090202-L 9.52 5.56 2.38 0.20 3.00 • • • • 1.00-2.00 0.10-0.20 TPGX 090204-L 9.52 5.56 2.38 0.40 3.00 • • • • 1.00-2.50 0.15-0.20 TPGX 110302-L 11.00 6.35 3.18 0.20 3.50 • • • • 1.00-2.50 0.10-0.20 TPGX 110304-L 11.00 6.35 3.18 0.40 3.50 • • • • 1.00-3.00 0.15-0.20 TPGX 110308-L 11.00 6.35 3.18 0.80 3.50 • 1.00-3.50 0.15-0.25 For tools, see pages: IHAXF (432) • IHAXF-AVI (434) • IHAXF-E (434) • IHFF (436) • IHFF-C (413) 459

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления