Каталог Iscar отрезка 2022 - страница 70

Навигация

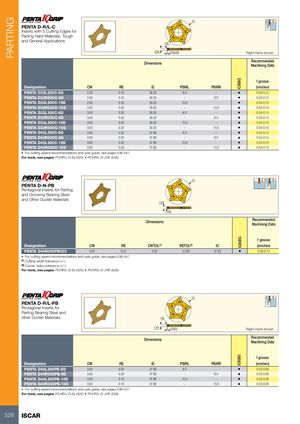

PARTING IC808GIC808GIC808G IC PENTA D-R/L-C Inserts with 5 Cutting Edges for Parting Hard Materials, Tough and General Applications RE CW PSIRR Right-hand shown Dimensions RecommendedMachining Data f groove Designation CW RE IC PSIRL PSIRR (mm/rev) PENTA D32L200C-6D 2.00 0.10 30.25 6.0 - • 0.04-0.12 PENTA D32R200C-6D 2.00 0.10 30.25 - 6.0 • 0.04-0.12 PENTA D32L200C-15D 2.00 0.20 30.25 15.0 - • 0.04-0.10 PENTA D32R200C-15D 2.00 0.20 30.25 - 15.0 • 0.04-0.10 PENTA D32L300C-6D 3.00 0.20 30.25 6.0 - • 0.04-0.14 PENTA D32R300C-6D 3.00 0.20 30.25 - 6.0 • 0.04-0.14 PENTA D32L300C-15D 3.00 0.20 30.25 15.0 - • 0.04-0.10 PENTA D32R300C-15D 3.00 0.20 30.25 - 15.0 • 0.04-0.10 PENTA D40L300C-6D 3.00 0.20 37.80 6.0 - • 0.04-0.14 PENTA D40R300C-6D 3.00 0.20 37.80 - 6.0 • 0.04-0.14 PENTA D40L300C-15D 3.00 0.20 37.80 15.0 - • 0.04-0.10 PENTA D40R300C-15D 3.00 0.20 37.80 - 15.0 • 0.04-0.10 • For cutting speed recommendations and user guide, see pages 538-547 For tools, see pages: PCHR/L-D-IQ (525) • PCHR/L-D-JHP (526) IC PENTA D-N-PB Pentagonal Inserts for Parting and Grooving Bearing Steel and Other Ductile Materials CW RE Dimensions RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) IC (mm/rev) PENTA D40N300PB020 3.00 0.20 0.02 0.030 37.80 • 0.03-0.10 • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: PCHR/L-D-IQ (525) • PCHR/L-D-JHP (526) IC PENTA D-R/L-PB Pentagonal Inserts for Parting Bearing Steel and other Ductile Materials RE CW PSIR Right-hand shown Dimensions RecommendedMachining Data f groove Designation CW RE IC PSIRL PSIRR (mm/rev) PENTA D40L300PB-6D 3.00 0.20 37.80 6.0 - • 0.03-0.08 PENTA D40R300PB-6D 3.00 0.20 37.80 - 6.0 • 0.03-0.08 PENTA D40L300PB-15D 3.00 0.10 37.80 15.0 - • 0.03-0.06 PENTA D40R300PB-15D 3.00 0.10 37.80 - 15.0 • 0.03-0.06 • For cutting speed recommendations and user guide, see pages 538-547 For tools, see pages: PCHR/L-D-IQ (525) • PCHR/L-D-JHP (526) 528 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022