Каталог Iscar обработка канавок 2022 - страница 70

Навигация

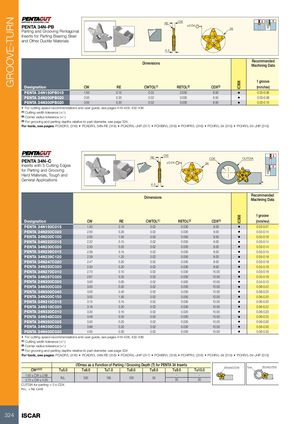

GROOVE-TURN IC908IC908 RE CW PENTA 34N-PB ±0.04 34 Parting and Grooving Pentagonal Inserts for Parting Bearing Steel and Other Ductile Materials 4.3 Dimensions RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) (mm/rev) PENTA 34N150PB015 1.50 0.15 0.02 0.030 8.50 • 0.03-0.06 PENTA 34N200PB020 2.00 0.20 0.02 0.030 8.50 • 0.03-0.08 PENTA 34N300PB020 3.00 0.20 0.02 0.030 9.50 • 0.03-0.10 • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) For grooving and parting depths relative to part diameter, see page 324 For tools, see pages: PCADR/L (316) • PCADR/L 34N-RE (318) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-34 (315) • PCHR/L-34-JHP (315) PENTA 34N-CInserts with 5 Cutting Edges RE CW CDX CUTDIA±0.0434 for Parting and Grooving Hard Materials, Tough and General Applications 4.3 Dimensions RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) (mm/rev) PENTA 34N150C015 1.50 0.15 0.02 0.030 8.00 • 0.03-0.07 PENTA 34N200C020 2.00 0.20 0.02 0.030 8.00 • 0.04-0.14 PENTA 34N200C100 2.00 1.00 0.02 0.050 8.00 • 0.05-0.16 PENTA 34N222C015 2.22 0.15 0.02 0.030 8.00 • 0.05-0.14 PENTA 34N230C020 2.30 0.20 0.02 0.030 8.00 • 0.05-0.14 PENTA 34N239C015 2.39 0.15 0.02 0.030 8.00 • 0.05-0.15 PENTA 34N239C120 2.39 1.20 0.02 0.050 8.00 • 0.05-0.18 PENTA 34N247C020 2.47 0.20 0.02 0.030 8.00 • 0.05-0.18 PENTA 34N250C020 2.50 0.20 0.02 0.030 8.00 • 0.05-0.18 PENTA 34N270C010 2.70 0.10 0.02 0.030 10.00 • 0.05-0.18 PENTA 34N287C020 2.87 0.20 0.02 0.030 10.00 • 0.05-0.18 PENTA 34N300C000 3.00 0.00 0.02 0.000 10.00 • 0.04-0.10 PENTA 34N300C020 3.00 0.20 0.02 0.030 10.00 • 0.06-0.22 PENTA 34N300C040 3.00 0.40 0.02 0.030 10.00 • 0.06-0.25 PENTA 34N300C150 3.00 1.50 0.02 0.050 10.00 • 0.06-0.20 PENTA 34N315C015 3.15 0.15 0.02 0.030 10.00 • 0.06-0.20 PENTA 34N318C020 3.18 0.20 0.02 0.030 10.00 • 0.06-0.22 PENTA 34N330C010 3.30 0.10 0.02 0.020 10.00 • 0.06-0.20 PENTA 34N348C020 3.48 0.20 0.02 0.030 10.00 • 0.06-0.25 PENTA 34N350C025 3.50 0.25 0.02 0.030 10.00 • 0.06-0.30 PENTA 34N398C020 3.98 0.20 0.02 0.030 10.00 • 0.06-0.30 PENTA 34N400C030 4.00 0.30 0.02 0.030 10.00 • 0.06-0.30 • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) For grooving and parting depths relative to part diameter, see page 324 For tools, see pages: PCADR/L (316) • PCADR/L 34N-RE (318) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-34 (315) • PCHR/L-34-JHP (315) ØDmax as a Function of Parting / Grooving Depth (T) for PENTA 34 Inserts CW±0.02 T≤5.0 T≤6.0 T≤7.0 T≤8.0 T≤8.5 T≤9.0 T≤10.0 ØDmax(CUTDIA) Tmax ØDmax(CUTDIA) 1.50 ≤ CW ≤ 2.692.70 ≤ CW ≤ 4.00N.L. 350 165 100 55 -55 -20 CUTDIA for parting = 2 x CDX N.L. = No Limit 324 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022