Каталог Iscar обработка канавок 2022 - страница 51

Навигация

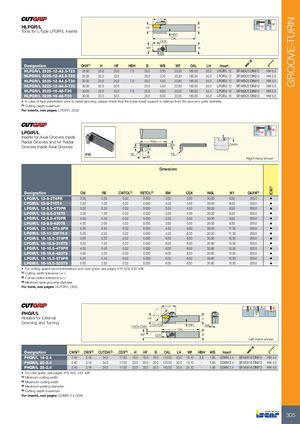

IC907 GROOVE-TURN LH HLPGR/L HF H Tools for L-Type LPGIR/L Inserts HBH OAL OHX WF B WB Designation OHX(1) H HF HBH B WB WF OAL LH Insert HLPGR/L 2525-12-A3.5-T25 25.00 25.0 25.0 7.0 25.0 3.50 23.30 160.00 50.0 LPGIR/L 12 SR M6X20 DIN912 HW 5.0 HLPGR/L 3225-12-A3.5-T25 25.00 32.0 32.0 - 25.0 3.50 23.30 160.00 50.0 LPGIR/L 12 SR M6X20 DIN912 HW 5.0 HLPGR/L 2525-12-A4.5-T30 30.00 25.0 25.0 7.0 25.0 4.50 22.80 160.00 55.0 LPGIR/L 12 SR M6X20 DIN912 HW 5.0 HLPGR/L 3225-12-A4.5-T30 30.00 32.0 32.0 - 25.0 4.50 22.80 160.00 55.0 LPGIR/L 12 SR M6X20 DIN912 HW 5.0 HLPGR/L 2525-16-A6-T30 30.00 25.0 25.0 7.0 25.0 6.00 22.00 160.00 55.0 LPGIR/L 16 SR M6X20 DIN912 HW 5.0 HLPGR/L 3225-16-A6-T30 30.00 32.0 32.0 - 25.0 6.00 22.00 160.00 55.0 LPGIR/L 16 SR M6X20 DIN912 HW 5.0 • In case of face penetration prior to radial grooving, please check that the lower insert support is relieved from the groove's outer diameter (1) Cutting depth maximum For inserts, see pages: LPGIR/L (305) LPGIR/L Inserts for Axial Grooves Inside Radial Grooves and for Radial INSL Grooves Inside Axial Grooves BW DAXNW1CDX RE RE CW Right-hand shown Dimensions Designation CW RE CWTOL(1) RETOL(2) BW CDX INSL W1 DAXN(3) LPGIR/L 12-8-2T4PR 2.00 0.20 0.02 0.030 4.00 3.50 30.00 8.00 200.0 • LPGIR/L 12-8-210T4 2.00 1.00 0.02 0.030 4.00 3.50 30.00 8.00 200.0 • LPGIR/L 12-8.5-3T5PR 3.00 0.30 0.02 0.030 3.50 4.50 30.00 8.50 200.0 • LPGIR/L 12-8.5-315T5 3.00 1.50 0.02 0.030 3.50 4.50 30.00 8.50 200.0 • LPGIR/L 12-9.5-4T6PR 4.00 0.40 0.02 0.030 3.50 5.50 30.00 9.50 200.0 • LPGIR/L 12-9.5-420T6 4.00 2.00 0.02 0.030 3.50 5.50 30.00 9.50 200.0 • LPGIR/L 12-11-5T6.5PR 5.00 0.40 0.02 0.030 4.50 6.00 30.00 11.00 200.0 • LPGIR/L 12-11-525T6.5 5.00 2.50 0.02 0.030 4.50 6.00 30.00 11.00 200.0 • LPGIR/L 16-15.5-3T9PR 3.00 0.30 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • LPGIR/L 16-15.5-315T9 3.00 1.50 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • LPGIR/L 16-15.5-4T9PR 4.00 0.40 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • LPGIR/L 16-15.5-420T9 4.00 2.00 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • LPGIR/L 16-15.5-5T9PR 5.00 0.40 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • LPGIR/L 16-15.5-525T9 5.00 2.50 0.02 0.030 6.00 8.50 30.60 15.50 200.0 • • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) Minimum axial grooving diameter For tools, see pages: HLPGR/L (305) LH PHGR/L Holders for External HF H Grooving and Turning CWN-CWX CUTDIA HBH WB OAL WF CDX B Left-hand shown Designation CWN(1) CWX(2) CUTDIA(3) CDX(4) H HF B OAL LH WF HBH WB Insert PHGR/L 16-2.4 2.40 3.18 34.0 17.00 16.0 16.0 16.0 110.00 33.0 15.10 5.5 1.90 GDMW 2.4 SR M5X16 DIN912 HW 4.0 PHGR/L 20-2.4 2.40 3.18 34.0 17.00 20.0 20.0 20.0 120.00 33.0 19.10 - 1.90 GDMW 2.4 SR M5X16 DIN912 HW 4.0 PHGR/L 25-2.4 2.40 3.18 34.0 17.00 25.0 25.0 25.0 140.00 33.0 24.10 - 1.90 GDMW 2.4 SR M5X16 DIN912 HW 4.0 • For user guide, see pages 419-428, 432-436 (1) Minimum cutting width (2) Maximum cutting width (3) Maximum parting diameter. (4) Cutting depth maximum For inserts, see pages: GDMW 2.4 (306) 305

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022