Каталог Iscar концевые фрезы со сменными пластинами 2022 - страница 79

Навигация

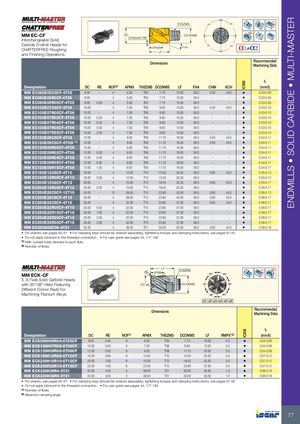

IC908IC908 ENDMILLS • SOLID CARBIDE • MULTI-MASTER Rd° THSZMS α1 α2 MM EC-CFInterchangeable Solid DC DCONMSCHWx45°/RE Carbide Endmill Heads forCHATTERFREE Roughing APMX FHA α2 α1 LF and Finishing Operations Dimensions RecommendedMachining Data fz Designation DC RE NOF(2) APMX THSZMS DCONMS LF FHA CHW KCH (mm/t) MM EC080E05C3CF-4T05 8.00 - 4 5.00 T05 7.70 10.00 38.0 0.30 45.0 • 0.03-0.09 MM EC080E05R0CF-4T05 8.00 - 4 5.00 T05 7.70 10.00 38.0 - - • 0.03-0.09 MM EC080E05R05CF-4T05 8.00 0.50 4 5.00 T05 7.70 10.00 38.0 - - • 0.03-0.09 MM EC100E07C4CF-4T06 10.00 - 4 7.00 T06 9.60 13.00 38.0 0.40 45.0 • 0.03-0.10 MM EC100E07R00CF-4T06 10.00 - 4 7.00 T06 9.60 13.00 38.0 - - • 0.03-0.10 MM EC100E07R02CF-4T06 10.00 0.20 4 7.00 T06 9.60 13.00 38.0 - - • 0.03-0.10 MM EC100E07R04CF-4T06 10.00 0.40 4 7.00 T06 9.60 13.00 38.0 - - • 0.03-0.10 MM EC100E07R05CF-4T06 10.00 0.50 4 7.00 T06 9.60 13.00 38.0 - - • 0.03-0.10 MM EC100E07R25CF-4T06 10.00 2.50 4 7.00 T06 9.60 13.00 38.0 - - • 0.03-0.10 MM EC120E09C5CF-4T08 12.00 - 4 9.00 T08 11.70 16.50 38.0 0.50 45.0 • 0.04-0.11 MM EC120E09C5CF-4T08I (1) 12.00 - 4 9.00 T08 11.70 16.50 38.0 0.50 45.0 • 0.04-0.11 MM EC120E09R00CF-4T08 12.00 - 4 9.00 T08 11.70 16.50 38.0 - - • 0.04-0.11 MM EC120E09R02CF-4T08 12.00 0.20 4 9.00 T08 11.70 16.50 38.0 - - • 0.04-0.11 MM EC120E09R04CF-4T08 12.00 0.40 4 9.00 T08 11.70 16.50 38.0 - - • 0.04-0.11 MM EC120E09R05CF-4T08 12.00 0.50 4 9.00 T08 11.70 16.50 38.0 - - • 0.04-0.11 MM EC120E09R15CF-4T08 12.00 1.50 4 9.00 T08 11.70 16.50 38.0 - - • 0.04-0.11 MM EC160E12C6CF-4T10 16.00 - 4 12.00 T10 15.30 20.50 38.0 0.60 45.0 • 0.05-0.13 MM EC160E12R05CF-4T10 16.00 0.50 4 12.00 T10 15.30 20.50 38.0 - - • 0.05-0.13 MM EC200E15C6CF-4T12 20.00 - 4 15.00 T12 18.45 25.50 38.0 0.60 45.0 • 0.05-0.17 MM EC200E15R05CF-4T12 20.00 0.50 4 15.00 T12 18.45 25.50 38.0 - - • 0.05-0.17 MM EC250E28C6CF-12T15 25.00 - 12 28.00 T15 23.90 43.00 38.0 0.60 45.0 • 0.06-0.13 MM EC250E28C6CF-4T15 25.00 - 4 28.00 T15 23.90 43.00 38.0 0.60 45.0 • 0.06-0.17 MM EC250E22C6CF-4T15 25.00 - 4 22.00 T15 23.90 37.00 38.0 0.60 45.0 • 0.06-0.17 MM EC250E22R05CF-4T15 25.00 0.50 4 22.00 T15 23.90 37.00 38.0 - - • 0.06-0.17 MM EC250E22R10CF-4T15 25.00 1.00 4 22.00 T15 23.90 37.00 38.0 - - • 0.06-0.17 MM EC250E22R20CF-4T15 25.00 2.00 4 22.00 T15 23.90 37.00 38.0 - - • 0.06-0.17 MM EC250E22R30CF-4T15 25.00 3.00 4 22.00 T15 23.90 37.00 38.0 - - • 0.06-0.17 MM EC320H38C06-4T21 32.00 - 4 38.00 T21 30.00 55.00 38.0 0.60 45.0 • 0.06-0.18 • For shanks, see pages 84-91 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 91-92 • Do not apply lubricant to the threaded connection. • For user guide see pages 44, 177-184 (1) With coolant holes directed to each flute (2) Number of flutes MM ECK-CF LFREAPMX THSZMS a2° a3° Rd° 5, 6 Flute Solid Carbide Heads with 35°/38° Helix Featuring DC e8 DCONMS a1° a4° Different Corner Radii For Machining Titanium Alloys a6° a5° a1≠a2≠a3≠a4≠a5≠a6 Dimensions RecommendedMachining Data fz Designation DC RE NOF(1) APMX THSZMS DCONMS LF RMPX°(2) (mm/t) MM ECK080H05R04-6T05CF 8.00 0.40 6 5.00 T05 7.70 10.00 5.0 • 0.04-0.08 MM ECK100H07R05-6T06CF 10.00 0.50 6 7.00 T06 9.60 13.00 5.0 • 0.04-0.08 MM ECK120H09R05-6T08CF 12.00 0.50 6 9.00 T08 11.70 16.50 5.0 • 0.04-0.08 MM ECK160H12R08-6T10CF 16.00 0.80 6 12.00 T10 15.30 20.50 5.0 • 0.07-0.12 MM ECK200H15R10-6T12CF 20.00 1.00 6 15.00 T12 18.45 25.50 5.0 • 0.07-0.12 MM ECK250H22R10-6T15CF 25.00 1.00 6 22.00 T15 23.90 37.00 5.0 • 0.07-0.12 MM ECK320H38R4-5T21 32.00 4.00 5 38.00 T21 30.00 55.00 1.0 • 0.06-0.18 MM ECK320H38R5-5T21 32.00 5.00 5 38.00 T21 30.00 55.00 1.0 • 0.06-0.18 • For shanks, see pages 84-91 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 91-92 • Do not apply lubricant to the threaded connection. • For user guide see pages 44, 177-184 (1) Number of flutes (2) Maximum ramping angle 77

Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022