Каталог Iscar концевые фрезы со сменными пластинами 2022 - страница 47

Навигация

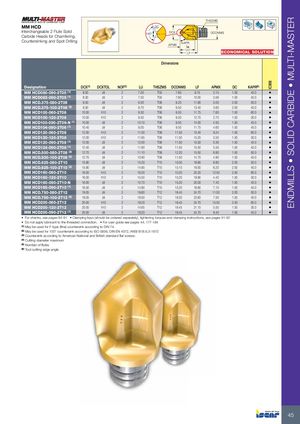

IC908 ENDMILLS • SOLID CARBIDE • MULTI-MASTER THSZMS MM HCD DC Interchangeable 2 Flute SolidCarbide Heads for Chamfering, 140° DCX DCONMS Countersinking and Spot Drilling APMX KAPR LULF ECONOMICAL SOLUTION Dimensions Designation DCX(4) DCXTOL NOF(5) LU THSZMS DCONMS LF APMX DC KAPR(6) MM HCD080-090-2T05 (1) 8.00 z9 2 7.00 T05 7.60 9.75 3.15 1.00 45.0 • MM HCD083-090-2T05 (1) 8.30 z9 2 7.50 T05 7.60 10.00 3.56 1.00 45.0 • MM HCD.375-080-2T06 9.50 z9 2 9.00 T06 9.20 11.80 5.00 2.00 50.0 • MM HCD.375-100-2T06 (2) 9.50 z9 2 9.70 T06 9.50 13.40 3.60 2.00 40.0 • MM HCD100-060-2T06 10.00 h10 2 9.30 T06 9.50 11.75 7.60 1.50 60.0 • MM HCD100-120-2T06 10.00 h10 2 9.50 T06 9.50 12.70 2.70 1.50 30.0 • MM HCD100-090-2T06-N (1) 10.00 z9 2 10.10 T06 9.50 14.00 4.50 1.50 45.0 • MM HCD104-090-2T06 (1) 10.40 z9 2 9.00 T06 9.50 11.75 4.60 1.50 45.0 • MM HCD120-060-2T08 12.00 h10 2 11.00 T08 11.50 15.40 9.24 1.50 60.0 • MM HCD120-120-2T08 12.00 h10 2 11.65 T08 11.50 15.20 3.50 1.50 30.0 • MM HCD120-090-2T08 (1) 12.00 z9 2 12.00 T08 11.50 15.50 5.30 1.50 45.0 • MM HCD124-090-2T08 (1) 12.40 z9 2 11.80 T08 11.50 15.50 5.50 1.50 45.0 • MM HCD.500-080-2T08 (3) 12.70 z9 2 11.10 T08 12.20 15.50 6.80 1.50 50.0 • MM HCD.500-100-2T08 (2) 12.70 z9 2 10.90 T08 11.50 14.70 4.90 1.50 40.0 • MM HCD.625-080-2T10 15.90 z9 2 15.20 T10 15.00 18.80 8.80 2.00 50.0 • MM HCD.625-100-2T10 (2) 15.90 z9 2 14.90 T10 15.10 19.00 6.20 2.00 40.0 • MM HCD160-060-2T10 16.00 h10 2 16.20 T10 15.20 20.20 12.00 2.50 60.0 • MM HCD160-120-2T10 16.00 h10 2 15.50 T10 15.20 19.90 4.40 1.50 30.0 • MM HCD160-090-2T10-N 16.00 z9 2 15.70 T10 15.20 20.00 7.40 1.50 45.0 • MM HCD165-090-2T10 (1) 16.50 z9 2 14.90 T10 15.20 18.80 7.10 1.50 45.0 • MM HCD.750-080-2T12 19.05 z9 2 19.60 T12 18.45 24.70 11.00 2.00 50.0 • MM HCD.750-100-2T12 (2) 19.05 z9 2 18.50 T12 18.30 23.60 7.50 1.50 40.0 • MM HCD200-060-2T12 20.00 h10 2 18.20 T12 18.45 24.70 15.50 2.50 60.0 • MM HCD200-120-2T12 20.00 h10 2 14.65 T12 18.45 21.15 5.50 1.50 30.0 • MM HCD200-090-2T12 (1) 20.00 z9 2 18.20 T12 18.45 24.70 9.40 1.50 45.0 • • For shanks, see pages 84-91 • Clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 91-92 • Do not apply lubricant to the threaded connection. • For user guide see pages 44, 177-184 (1) May be used for F-type (fine) countersink according to DIN 74. (2) May be used for 100° countersink according to ISO 5856, DIN EN 4072, ANSI B18.6.3-1972 (3) Countersink according to American National and British standard flat screws. (4) Cutting diameter maximum (5) Number of flutes (6) Tool cutting edge angle 45

Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022