Каталог Iscar инструментальная оснастка 2022 - страница 177

Навигация

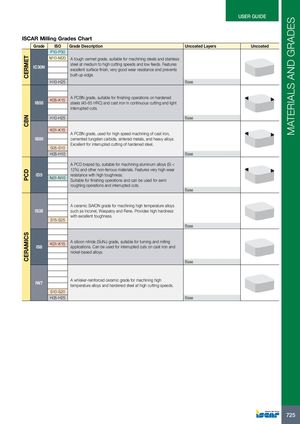

CERMETCBNPCDCERAMICS MATERIALS AND GRADES USER GUIDE ISCAR Milling Grades Chart Grade ISO Grade Description Uncoated Layers Uncoated P10-P30 M10-M20 A tough cermet grade, suitable for machining steels and stainless IC30N steel at medium to high cutting speeds and low feeds. Featuresexcellent surface finish, very good wear resistance and prevents built-up edge. H10-H25 Base IB55 K05-K15 A PCBN grade, suitable for finishing operations on hardenedsteels (45-65 HRC) and cast iron in continuous cutting and light interrupted cuts. H10-H25 Base K01-K15 A PCBN grade, used for high speed machining of cast iron, IB85 cemented tungsten carbide, sintered metals, and heavy alloys. Excellent for interrupted cutting of hardened steel. S05-S10 H05-H10 Base A PCD brazed tip, suitable for machining aluminum alloys (Si < 12%) and other non-ferrous materials. Features very high wear ID5 N01-N10 resistance with high toughness.Suitable for finishing operations and can be used for semi roughing operations and interrupted cuts. Base A ceramic SiAlON grade for machining high temperature alloys IS35 such as Inconel, Waspaloy and Rene. Provides high hardness with excellent toughness. S15-S25 Base K01-K15 A silicon nitride (Si3N4) grade, suitable for turning and milling IS8 applications. Can be used for interrupted cuts on cast iron and nickel-based alloys. Base IW7 A whisker-reinforced ceramic grade for machining hightemperature alloys and hardened steel at high cutting speeds. S10-S20 H05-H25 Base 725

Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar обработка канавок 2022

Каталог Iscar обработка канавок 2022 Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018