Каталог Iscar инструментальная оснастка 2022 - страница 176

Навигация

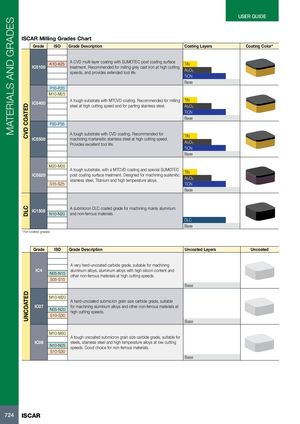

MATERIALS AND GRADES CVD COATEDDLCUNCOATED USER GUIDE ISCAR Milling Grades Chart Grade ISO Grade Description Coating Layers Coating Color* IC5100 K10-K25 A CVD multi-layer coating with SUMOTEC post coating surfacetreatment. Recommended for milling grey cast iron at high cuttingTiN speeds, and provides extended tool life. Al2O3 TiCN Base P10-P20 M10-M25 IC5400 A tough substrate with MTCVD coating. Recommended for milling TiNsteel at high cutting speed and for parting stainless steel.Al2O3 TiCN Base P20-P35 A tough substrate with CVD coating. Recommended for TiN IC5500 machining martensitic stainless steel at high cutting speed. Provides excellent tool life. Al2O3 TiCN Base M20-M35 A tough substrate, with a MTCVD coating and special SUMOTEC TiN IC5820 post coating surface treatment. Designed for machining austeniticstainless steel, Titanium and high temperature alloys.Al2O3 S15-S25 TiCN Base IC1508 N10-N20 A submicron DLC coated grade for machining mainly aluminumand non-ferrous materials. DLC Base * For coated grades Grade ISO Grade Description Uncoated Layers Uncoated A very hard-uncoated carbide grade, suitable for machining IC4 aluminum alloys, aluminum alloys with high silicon content and N05-N15 other non-ferrous materials at high cutting speeds. S05-S15 Base M10-M20 A hard-uncoated submicron grain size carbide grade, suitable IC07 for machining aluminum alloys and other non-ferrous materials at N05-N20 high cutting speeds. S10-S30 Base M10-M30 A tough uncoated submicron grain size carbide grade, suitable for IC08 steels, stainless steel and high temperature alloys at low cuttingN10-N25speeds. Good choice for non-ferrous materials. S10-S30 Base 724 ISCAR

Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar обработка канавок 2022

Каталог Iscar обработка канавок 2022 Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018