Каталог Iscar инструмента для сверления - страница 16

Навигация

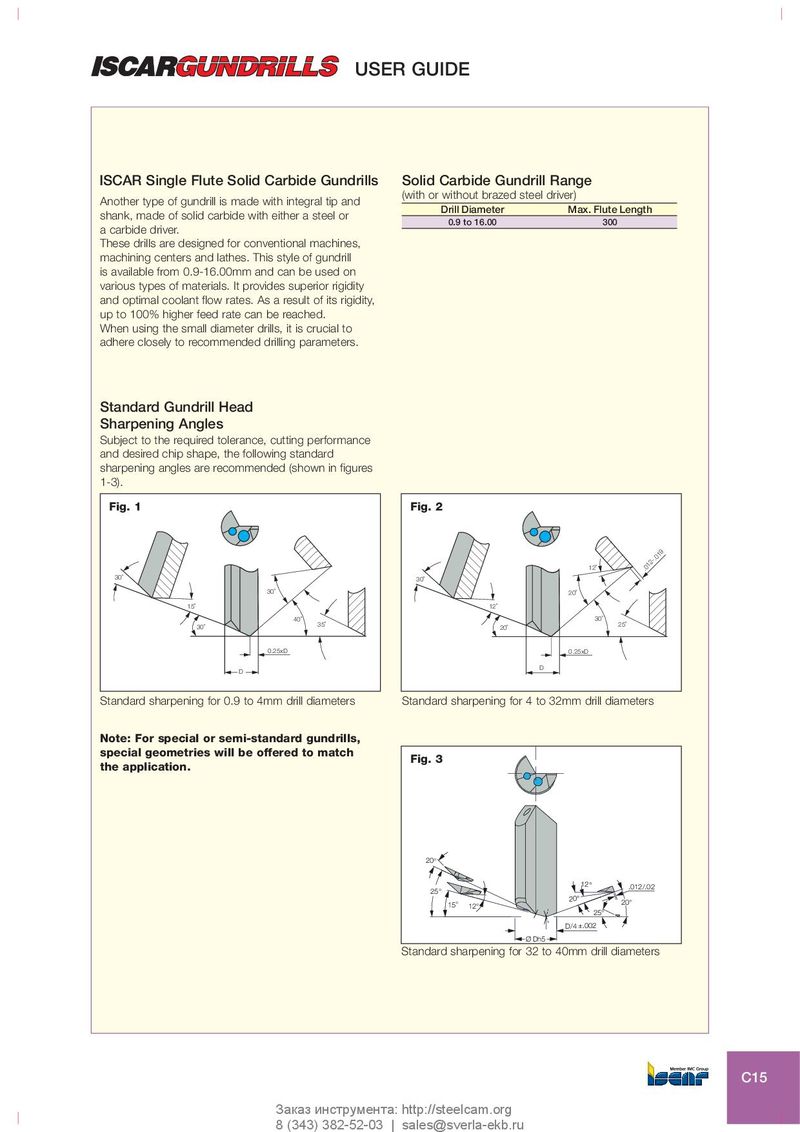

USER GUIDE ISCAR Single Flute Solid Carbide Gundrills Solid Carbide Gundrill Range (with or without brazed steel driver) Another type of gundrill is made with integral tip and Drill Diameter Max. Flute Length shank, made of solid carbide with either a steel or 0.9 to 16.00 300 a carbide driver. These drills are designed for conventional machines, machining centers and lathes. This style of gundrill is available from 0.9-16.00mm and can be used on various types of materials. It provides superior rigidity and optimal coolant flow rates. As a result of its rigidity, up to 100% higher feed rate can be reached. When using the small diameter drills, it is crucial to adhere closely to recommended drilling parameters. Standard Gundrill Head Sharpening Angles Subject to the required tolerance, cutting performance and desired chip shape, the following standard sharpening angles are recommended (shown in figures 1-3). Fig. 1 Fig. 2 12˚ .012-.019 30˚ 30˚ 30˚ 20˚ 15˚ 12˚ 40˚ 30˚ 30˚ 35˚ 20˚ 25˚ 0.25xD 0.25xD D D Standard sharpening for 0.9 to 4mm drill diameters Standard sharpening for 4 to 32mm drill diameters Note: For special or semi-standard gundrills, special geometries will be offered to match Fig. 3 the application. 20° 12° .012/.02 25° 20° 15° 20° 12° 25° D/4 ±.002 Ø Dh5 Standard sharpening for 32 to 40mm drill diameters C15 Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки