Каталог Iscar инструмента для сверления - страница 15

Навигация

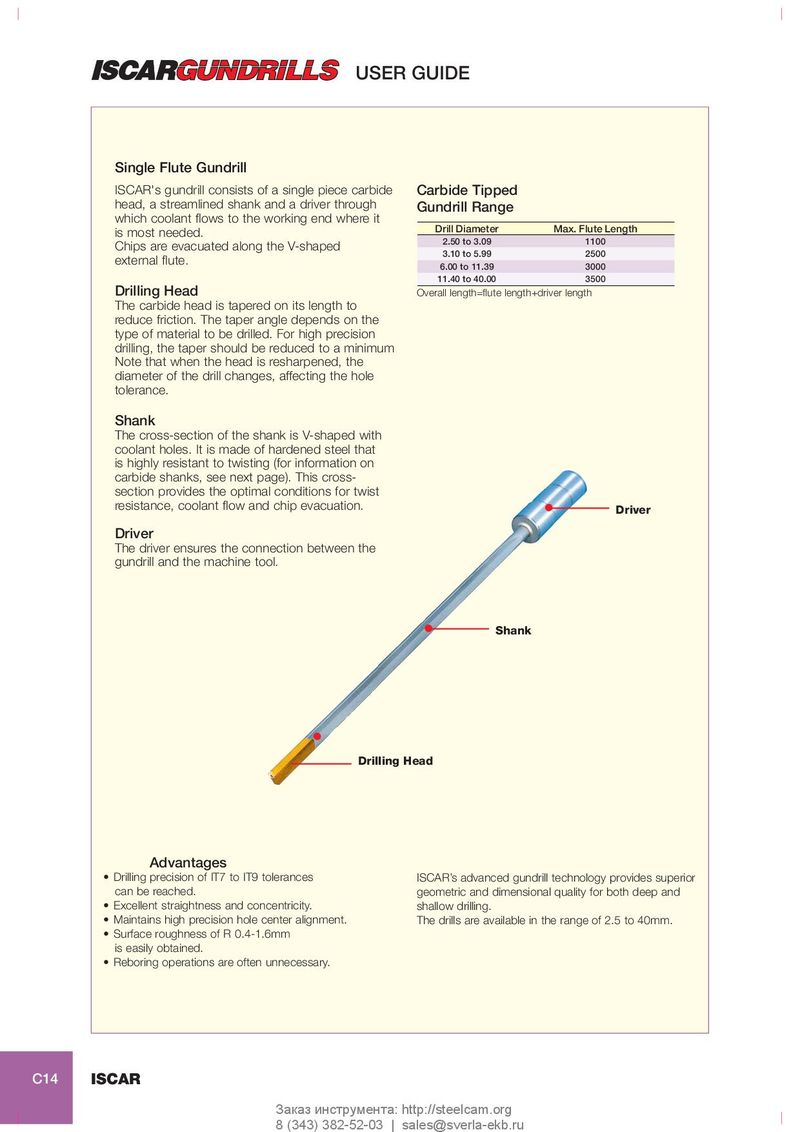

USER GUIDE Single Flute Gundrill ISCAR's gundrill consists of a single piece carbide Carbide Tipped head, a streamlined shank and a driver through Gundrill Range which coolant flows to the working end where it Drill Diameter Max. Flute Length is most needed. 2.50 to 3.09 1100 Chips are evacuated along the V-shaped 3.10 to 5.99 2500 external flute. 6.00 to 11.39 3000 11.40 to 40.00 3500 Drilling Head Overall length=flute length+driver length The carbide head is tapered on its length to reduce friction. The taper angle depends on the type of material to be drilled. For high precision drilling, the taper should be reduced to a minimum Note that when the head is resharpened, the diameter of the drill changes, affecting the hole tolerance. Shank The cross-section of the shank is V-shaped with coolant holes. It is made of hardened steel that is highly resistant to twisting (for information on carbide shanks, see next page). This cross- section provides the optimal conditions for twist resistance, coolant flow and chip evacuation. Driver Driver The driver ensures the connection between the gundrill and the machine tool. Shank Drilling Head Advantages • Drilling precision of IT7 to IT9 tolerances ISCAR’s advanced gundrill technology provides superior can be reached. geometric and dimensional quality for both deep and • Excellent straightness and concentricity. shallow drilling. • Maintains high precision hole center alignment. The drills are available in the range of 2.5 to 40mm. • Surface roughness of R 0.4-1.6mm is easily obtained. • Reboring operations are often unnecessary. C14 ISCAR Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки