Каталог Iscar инструмент для мелкоразмерной обработки - страница 39

Навигация

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar инструмент для внутренней обработки

Каталог Iscar инструмент для внутренней обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018

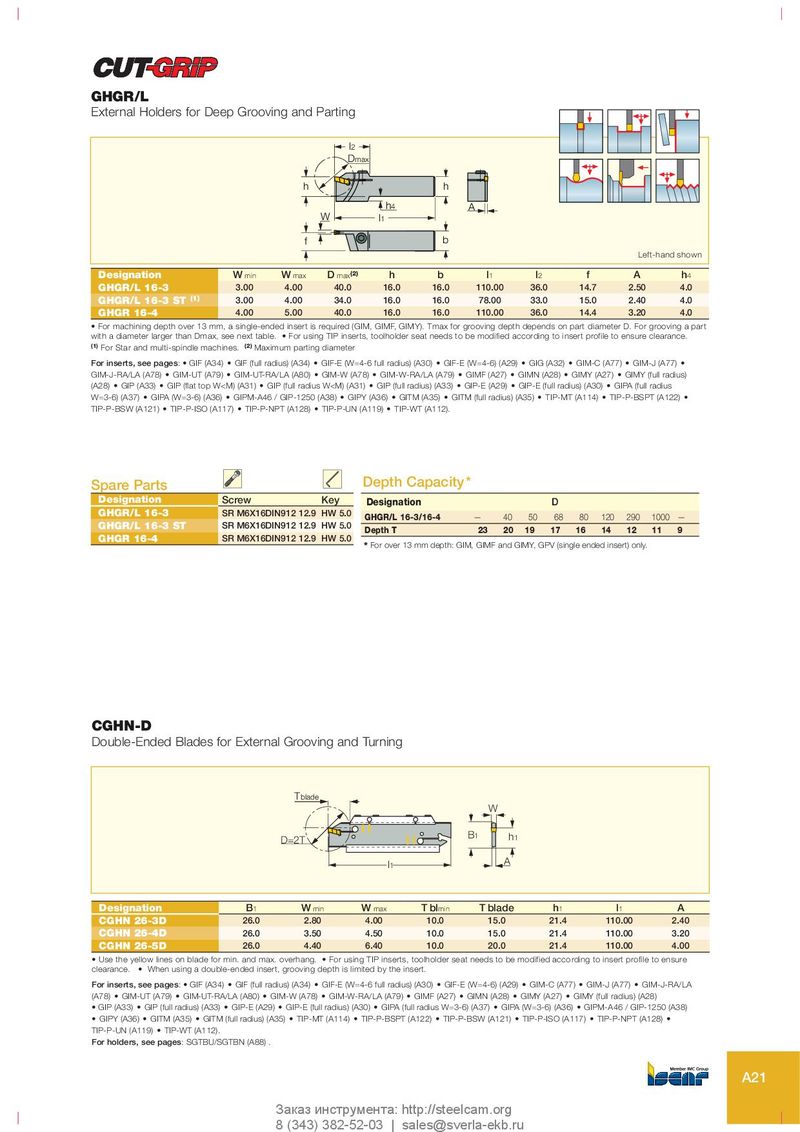

GHGR/L

External Holders for Deep Grooving and Parting

l2

Dmax

h h

h4 A

W l1

f b

Left-hand shown

Designation W min W max D max (2) h b l 1 l 2 f A h 4

GHGR/L 16-3 3.00 4.00 40.0 16.0 16.0 110.00 36.0 14.7 2.50 4.0

GHGR/L 16-3 ST (1) 3.00 4.00 34.0 16.0 16.0 78.00 33.0 15.0 2.40 4.0

GHGR 16-4 4.00 5.00 40.0 16.0 16.0 110.00 36.0 14.4 3.20 4.0

• For machining depth over 13 mm, a single-ended insert is required (GIM, GIMF, GIMY). Tmax for grooving depth depends on part diameter D. For grooving a part

with a diameter larger than Dmax, see next table. • For using TIP inserts, toolholder seat needs to be modified according to insert profile to ensure clearance.

(1) For Star and multi-spindle machines. (2) Maximum parting diameter

For inserts, see pages: • GIF (A34) • GIF (full radius) (A34) • GIF-E (W=4-6 full radius) (A30) • GIF-E (W=4-6) (A29) • GIG (A32) • GIM-C (A77) • GIM-J (A77) •

GIM-J-RA/LA (A78) • GIM-UT (A79) • GIM-UT-RA/LA (A80) • GIM-W (A78) • GIM-W-RA/LA (A79) • GIMF (A27) • GIMN (A28) • GIMY (A27) • GIMY (full radius)

(A28) • GIP (A33) • GIP (flat top W