Общий каталог Ingersoll 2011 - страница 462

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

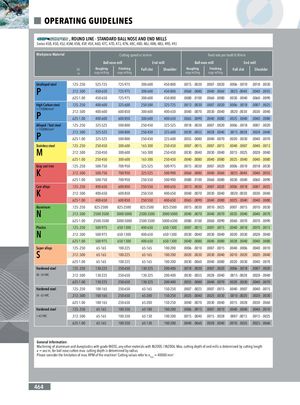

OPERATING GUIDELINES , ROUND LINE - STANDARD BALL NOSE AND END MILLS Series 45B, 45D, 45J, 45M, 45N, 45P, 45X, 46D, 47C, 47D, 47J, 47N, 48C, 48D, 48J, 48N, 48U, 49D, 49J Workpiece Material Cutting speed vc in/min Feed rate per tooth fz ft/min Ball nose mill End mill Ball nose mill End mill DC Roughing Finishing Full slot Shoulder Roughing Finishing Full slot Shoulder in copy milling copy milling copy milling copy milling Unalloyed steel .125-.250 525-725 725-975 300-600 450-800 .0015 - .0030 .0007 - .0020 .0006 - .0010 .0018 - .0030 P .312-.500 450-650 725-975 300-600 450-800 .0060 - .0080 .0040 - .0060 .0025 -.0040 .0040 - .0055 .625-1.00 450-650 725-975 300-600 450-800 .0080 - .0100 .0060 - .0080 .0030 - .0040 .0060 - .0090 High Carbon steel .125-.250 400-600 325-600 250-500 325-725 .0013 - .0030 .0007 - .0020 .0006 - .0018 .0007 - .0025 < 1100N/mm² P .312-.500 400-600 600-850 300-600 400-650 .0040 - .0070 .0030 - .0040 .0020 -.0030 .0030 - .0040.625-1.00400-600600-850300-600400-650.0065 - .0090.0040 - .0080.0025 - .0040.0040 - .0080 Alloyed / Tool steel .125-.250 325-525 500-800 250-450 325-525 .0018 - .0030 .0007 - .0020 .0006 - .0018 .0007 - .0020 < 1400N/mm² P .312-.500 325-525 500-800 250-450 325-600 .0030 - .0055 .0028 - .0040 .0015 -.0028 .0028 - .0040.625-1.00325-525500-800250-450325-600.0055 - .0080.0040 - .0070.0020 - .0030.0040 - .0070 Stainless steel .125-.250 250-450 300-600 165-300 250-450 .0007 - .0015 .0007 - .0015 .0040 - .0007 .0040 - .0013 M .312-.500 250-450 300-600 165-300 250-450 .0030 - .0040 .0030 - .0040 .0015 - .0025 .0028 - .0040 .625-1.00 250-450 300-600 165-300 250-450 .0040 - .0080 .0040 - .0080 .0025 - .0040 .0040 - .0080 Gray cast iron .125-.250 500-750 700-950 325-525 500-975 .0015 - .0030 .0007 - .0020 .0006 - .0010 .0018 - .0030 K .312-.500 500-750 700-950 325-525 500-900 .0060 - .0080 .0040 - .0060 .0025 -.0040 .0040 - .0055 .625-1.00 500-750 700-950 250-550 500-900 .0080 - .0100 .0060 - .0080 .0030 - .0040 .0060 - .0090 Cast alloys .125-.250 400-650 600-850 250-550 400-650 .0013 - .0030 .0007 - .0020 .0006 - .0018 .0007 - .0025 K .312-.500 400-650 600-850 250-550 400-650 .0040 - .0070 .0030 - .0040 .0020 -.0030 .0030 - .0040 .625-1.00 400-650 600-850 250-550 400-650 .0065 - .0090 .0040 - .0080 .0025 - .0040 .0040 - .0080 Aluminum .125-.250 825-2500 825-2500 825-2500 825-2500 .0015 - .0030 .0010 - .0025 .0007 - .0015 .0010 - .0030 N .312-.500 2500-3500 3000-5000 2500-3500 3000-5000 .0040 - .0070 .0040 - .0070 .0035 - .0040 .0040 - .0070 .625-1.00 2500-3500 3000-5000 2500-3500 5000-6500 .0080 - .0100 .0060 - .0090 .0060 - .0070 .0070 - .0090 Plastics .125-.250 500-975 650-1300 400-650 650-1300 .0007 - .0015 .0007 - .0015 .0040 - .0018 .0070 - .0015 N .312-.500 500-975 650-1300 400-650 650-1300 .0030 - .0040 .0030 - .0040 .0020 - .0030 .0028 - .0040 .625-1.00 500-975 650-1300 400-650 650-1300 .0040 - .0080 .0040 - .0080 .0028 - .0040 .0040 - .0080 Super alloys .125-.250 65-165 100-225 65-165 100-200 .0006 - .0010 .0007 - .0015 .0040 - .0006 .0040 - .0010 S .312-.500 65-165 100-225 65-165 100-200 .0020 - .0030 .0030 - .0040 .0010 - .0020 .0020 - .0040 .625-1.00 65-165 100-225 65-165 100-200 .0030 - .0060 .0040 - .0080 .0020 - .0030 .0040 - .0070 Hardened steel .125-.250 130-225 250-650 130-325 200-400 .0018 - .0030 .0007 - .0020 .0006 - .0018 .0007 - .0020 48 - 54 HRC .312-.500 130-225 250-650 130-325 200-400 .0030 - .0055 .0028 - .0040 .0015 -.0028 .0028 - .0040 .625-1.00 130-225 250-650 130-325 200-400 .0055 - .0080 .0040 - .0070 .0020 - .0030 .0040 - .0070 Hardened steel .125-.250 100-165 250-650 65-165 150-250 .0007 - .0025 .0007 - .0015 .0040 - .0007 .0040 - .0015 54 - 63 HRC .312-.500 100-165 250-650 65-200 150-250 .0025 - .0040 .0025 - .0030 .0010 -.0020 .0020 - .0030 .625-1.00 100-165 250-650 65-200 150-250 .0040 - .0070 .0030 - .0040 .0015 - .0028 .0030 - .0060 Hardened steel .125-.250 65-165 100-350 65-100 100-200 .0006 - .0015 .0007 - .0010 .0040 - .0040 .0040 - .0010 > 63 HRC .312-.500 65-165 100-350 65-130 100-200 .0015 - .0040 .0015 - .0028 .0007 -.0015 .0015 - .0025 .625-1.00 65-165 100-350 65-130 100-200 .0040 - .0060 .0028 - .0040 .0010 - .0025 .0025 - .0060 General Information: Machining of aluminum and duroplastics with grade IN05S, any other materials with IN2005 / IN2006. Max. cutting depth of end mills is determined by cutting length a = xxx in; for ball nose cutters max. cutting depth is determined by radius. Please consider the limitation of max. RPM of the machine! Cutting values refer to nmax = 40000 min-1 464

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021