Общий каталог Ingersoll 2011 - страница 1362

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

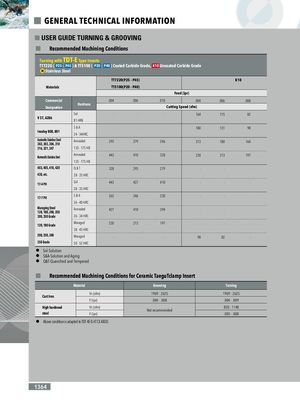

GENERAL TECHNICAL INFORMATION n USER GUIDE TURNING & GROOVING n Recommended Machining Conditions Turning with TDT-E Type Inserts TT7220 ( P25 - P45 ) & TT5100 ( P20 - P40 ) Coated Carbide Grade, K10 Uncoated Carbide Grade M Stainless Steel TT7220(P25 - P45) K10 Materials TT5100(P20 - P40) Feed (ipr) Commercial .004 .006 .010 .004 .006 .008 HardnessDesignation Cutting Speed (sfm) Sol - - - 164 115 82 V 57, A286 81 HRB S&A - - - 180 131 98 Incoloy 800, 801 24 - 34HRC Austenitic Stainless Steel Annealed302, 303, 304, 310295 279 246 213 180 164 316, 321, 347 135 - 175 HB Martensitic Stainless Steel Annealed 443 410 328 230 213 197 135 - 175 HB 403, 405, 410, 420 Q&T 328 295 279 - - - 430, etc. 28 - 35 HRC 17-4 PH Sol 443 427 410 - - - 28 - 35 HRC 17-7 PH S&A 262 246 230 - - - 36 - 40 HRC Maraging Steel Annealed120, 180, 200, 250427 410 394 - - - 300, 350 Grade 26 - 34 HRC 120, 180 Grade Maraged 230 213 197 - - - 38 - 45 HRC 200, 250, 300 Maraged - - - 98 82 - 350 Grade 50 - 52 HRC ••• Sol-SolutionS&A-Solution and AgingQ&T-Quenched and Tempered n Recommended Machining Conditions for Ceramic TaeguTclamp Insert Material Grooving Turning Vc (sfm) 1969 - 2625 1969 - 2625 Cast Iron F (ipr) .004 - .008 .004 - .009 High hardened Vc (sfm) 820 - 1148 Not recommended steel F (ipr) .003 - .008 • Above condition is adapted to TDT 4E-0.4T CE AB30. 1364

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021