Общий каталог Ingersoll 2011 - страница 1360

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

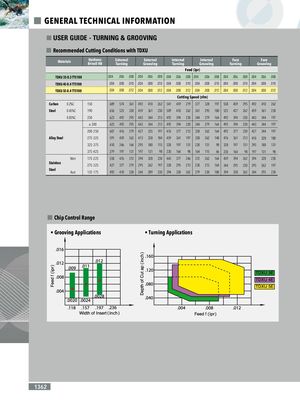

GENERAL TECHNICAL INFORMATION n USER GUIDE - TURNING & GROOVING n Recommended Cutting Conditions with TDXU Materials Hardness External External Internal Internal Face FaceBrinell HBTurningGroovingTurningGroovingTurningGrooving Feed (ipr) TDXU 3E-0.3 TT5100 .004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008 TDXU 4E-0.4 TT5100 .004 .008 .010 .004 .008 .010 .004 .008 .010 .004 .008 .010 .004 .008 .010 .004 .008 .010 TDXU 5E-0.4 TT5100 .004 .008 .012 .004 .008 .012 .004 .008 .012 .004 .008 .012 .004 .008 .012 .004 .008 .012 Cutting Speed (sfm) Carbon 0.2%C 150 689 574 361 492 410 262 541 459 279 377 328 197 558 459 295 492 410 262 Steel 0.45%C 190 656 525 328 459 361 230 509 410 262 361 295 180 525 427 262 459 361 230 0.83%C 250 623 492 29.5118443 34.415 213 492 394 230 344 279 164 492 394 230 443 344 197 ≤ 200 623 492 295 443 344 213 492 394 230 344 279 164 492 394 230 443 344 197 200 - 250 607 476 279 427 335 197 476 377 213 328 262 164 492 377 230 427 344 197 Alloy Steel 275 - 325 591 459 262 413 328 184 459 361 197 328 262 148 476 361 213 410 328 180 325 - 375 410 246 164 295 180 115 328 197 131 230 131 98 328 197 131 295 180 131 375 - 425 279 197 131 197 131 98 230 164 98 164 115 66 230 164 98 197 131 98 Mart 175 - 225 558 476 312 394 328 230 443 377 246 312 262 164 459 394 262 394 328 230 Stainless 275 - 325 427 377 279 295 262 197 328 295 213 230 213 164 344 295 230 295 262 197 Steel Aust 135 - 175 492 410 328 344 289 230 394 328 262 279 230 180 394 328 262 344 295 230 n Chip Control Range .118 .15 • Grooving Applications • Turning Applications 1362

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021