Каталог Guhring сверла со сменными пластинами - страница 36

Навигация

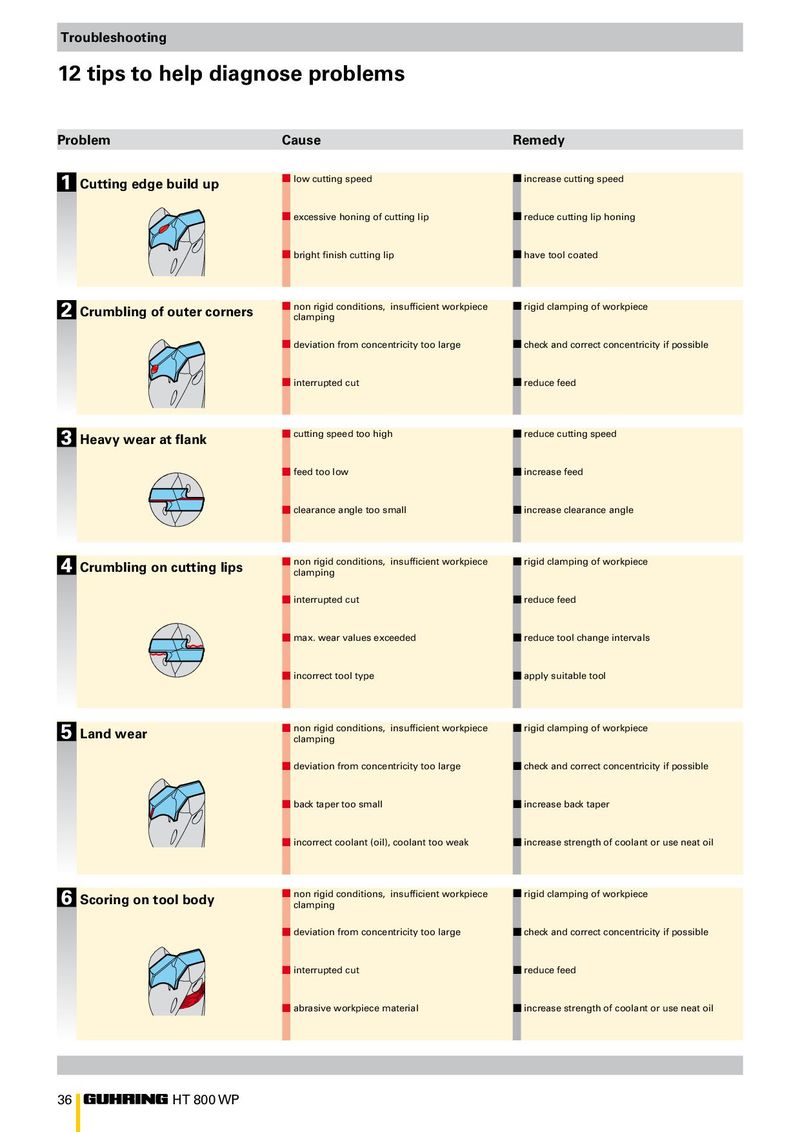

Troubleshooting 12 tips to help diagnose problems Problem Cause Remedy low cutting speed increase cutting speed Cutting edge build up excessive honing of cutting lip reduce cutting lip honing bright finish cutting lip have tool coated non rigid conditions, insufficient workpiece rigid clamping of workpiece Crumbling of outer corners clamping deviation from concentricity too large check and correct concentricity if possible interrupted cut reduce feed cutting speed too high reduce cutting speed Heavy wear at flank feed too low increase feed clearance angle too small increase clearance angle non rigid conditions, insufficient workpiece rigid clamping of workpiece Crumbling on cutting lips clamping interrupted cut reduce feed max. wear values exceeded reduce tool change intervals incorrect tool type apply suitable tool non rigid conditions, insufficient workpiece rigid clamping of workpiece Land wear clamping deviation from concentricity too large check and correct concentricity if possible back taper too small increase back taper incorrect coolant (oil), coolant too weak increase strength of coolant or use neat oil non rigid conditions, insufficient workpiece rigid clamping of workpiece Scoring on tool body clamping deviation from concentricity too large check and correct concentricity if possible interrupted cut reduce feed abrasive workpiece material increase strength of coolant or use neat oil 36 HT 800 WP

Каталог Guhring пластины PKD и CBN

Каталог Guhring пластины PKD и CBN Основной каталог Guhring 2011

Основной каталог Guhring 2011 Каталог Guhring резьбонарезной инструмент

Каталог Guhring резьбонарезной инструмент Каталог Guhring зенкеры и зенковки

Каталог Guhring зенкеры и зенковки Каталог Guhring резьбонарезной инструмент 2010

Каталог Guhring резьбонарезной инструмент 2010 Каталог Guhring высокопроизводительный инструмент по отличной цене SuperLine

Каталог Guhring высокопроизводительный инструмент по отличной цене SuperLine