Каталог Erojet монолитные резбофрезы - страница 30

Навигация

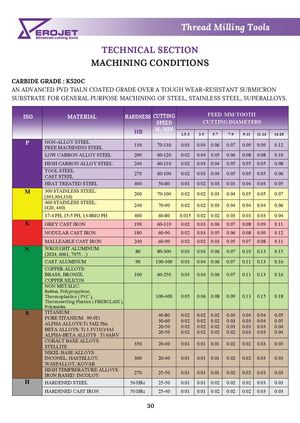

Thread Milling Tools TECHNICAL SECTION MACHINING CONDITIONS CARBIDE GRADE : K520C AN ADVANCED PVD TiALN COATED GRADE OVER A TOUGH WEAR-RESISTANT SUBMICRON SUBSTRATE FOR GENERAL PURPOSE MACHINING OF STEEL, STAINLESS STEEL, SUPERALLOYS. ISO MATERIAL HARDNESS CUTTING FEED MM/TOOTH SPEED CUTTING DIAMETERS HB M/MIN 1.5-3 3-5 5-7 7-9 9-11 11-14 14-20 P NON-ALLOY STEELFREE MACHINING STEEL 130 70-130 0.03 0.04 0.06 0.07 0.09 0.09 0.12 LOW CARBON ALLOY STEEL 200 60-120 0.02 0.04 0.05 0.06 0.08 0.08 0.10 HIGH CARBON ALLOY STEEL 240 60-110 0.02 0.03 0.04 0.05 0.05 0.05 0.08 TOOL STEELCAST STEEL 270 60-100 0.02 0.03 0.04 0.05 0.05 0.05 0.06 HEAT TREATED STEEL 400 50-80 0.01 0.02 0.03 0.03 0.04 0.04 0.05 M 300 STAINLESS STEEL:(303,304,316) 200 70-100 0.02 0.02 0.03 0.04 0.05 0.05 0.07 400 STAINLESS STEEL:(420, 440) 240 70-90 0.02 0.02 0.03 0.04 0.04 0.04 0.06 �17-4 PH, 15-5 PH, 13-8MO PH 400 60-80 0.015 0.02 0.02 0.03 0.03 0.03 0.04 K GREY CAST IRON 190 60-110 0.02 0.03 0.06 0.07 0.08 0.09 0.11 NODULAR CAST IRON 180 60-90 0.02 0.03 0.05 0.06 0.08 0.09 0.12 MALLEABLE CAST IRON 240 60-90 0.02 0.02 0.03 0.05 0.07 0.08 0.11 N WROUGHT ALUMINUM:(2024, 6061, 7075…) 80 80-300 0.03 0.04 0.06 0.07 0.10 0.13 0.15 CAST ALUMINUM 90 100-300 0.03 0.04 0.06 0.07 0.11 0.13 0.16 COPPER ALLOYS: BRASS, BRONZE, 100 60-250 0.03 0.04 0.06 0.07 0.11 0.13 0.16 COPPER SILICON NON METALIC: Rubber, Polypropylene, Thermoplastics ( PVC ), 100-400 0.05 0.06 0.08 0.09 0.13 0.15 0.18 Thermosetting Plastics ( FIBERGLASS ), Polyamides, S TITANIUM :PURE TITANIUM:99.0TiALPHA ALLOYS:Ti 5Al2.5SnBETA ALLOYS: Ti 1 3V11Cr3AlALPHA-BETA ALLOYS : Ti 6Al4V40-800.020.020.020.030.040.040.0530-600.020.020.020.030.030.040.0520-500.020.020.020.030.030.030.0420-500.020.020.020.020.030.030.04 COBALT BASE ALLOYS:STELLITE 350 20-40 0.01 0.01 0.01 0.02 0.02 0.03 0.03 NIKEL BASE ALLOYS: INCONEL, HASTELLOY, 300 20-40 0.01 0.01 0.01 0.02 0.02 0.03 0.03 WASPALLOY, KOVAR HIGH TEMPRERATURE ALLOYS:IRON BASED: INCOLOY270 25-50 0.01 0.01 0.01 0.02 0.02 0.03 0.03 H HARDENED STEEL 56 HRc 25-50 0.01 0.01 0.02 0.02 0.02 0.03 0.03 HARDENED CAST IRON 50 HRc 25-40 0.01 0.01 0.02 0.02 0.02 0.03 0.03 30

Каталог Erojet резьбонарезные пластины и державки

Каталог Erojet резьбонарезные пластины и державки