Общий каталог Dijet 2018 - страница 92

Навигация

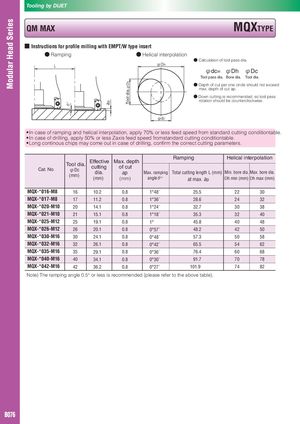

θ° ap Tool dia.φDc Tooling by DIJET QM MAX MQXTYPE ■ Instructions for profile milling with EMPT/W type insert ● Ramping ● Helical interpolation ● Calculation of tool pass dia. L φDh φdc= φDh φDc Tool pass dia. Bore dia. Tool dia. ● Depth of cut per one circle should not exceed max. depth of cut ap. ● Down cutting is recommended, so tool pass rotation should be counterclockwise. φdC ● In case of ramping and helical interpolation, apply 70% or less feed speed from standard cutting conditiontable. ● In case of drilling, apply 50% or less Zaxis feed speed fromstandard cutting conditiontable. ● Long continous chips may come out in case of drilling, confirm the correct cutting parameters. Ramping Helical interpolation Cat. No. Tool dia.φDc(mm)Effectivecuttingdia.(mm)Max. depthof cutap(mm)Max. rampingangleθ°Total cutting length L (mm)Min. bore dia. Max. bore dia.at max. apDh min (mm) Dh max (mm) MQX-*016-M8 16 10.2 0.8 1°48´ 25.5 22 30 MQX-*017-M8 17 11.2 0.8 1°36´ 28.6 24 32 MQX-*020-M10 20 14.1 0.8 1°24´ 32.7 30 38 MQX-*021-M10 21 15.1 0.8 1°18´ 35.3 32 40 MQX-*025-M12 25 19.1 0.8 1° 45.8 40 48 MQX-*026-M12 26 20.1 0.8 0°57´ 48.2 42 50 MQX-*030-M16 30 24.1 0.8 0°48´ 57.3 50 58 MQX-*032-M16 32 26.1 0.8 0°42´ 65.5 54 62 MQX-*035-M16 35 29.1 0.8 0°36´ 76.4 60 68 MQX-*040-M16 40 34.1 0.8 0°30´ 91.7 70 78 MQX-*042-M16 42 36.2 0.8 0°27´ 101.9 74 82 Note) The ramping angle 0.5° or less is recommended (please refer to the above table). B076

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском