Общий каталог Dijet 2018 - страница 91

Навигация

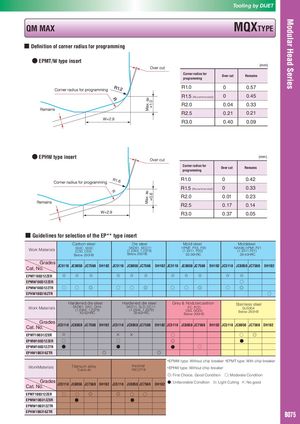

Tooling by DIJET QM MAX MQXTYPE ■ Definition of corner radius for programming ● EPMT/W type insert (mm) Corner radius forprogrammingOver cut Remains R1.0 0 0.57 R1.5 (Recommended) 0 0.45 R2.0 0.04 0.33 R2.5 0.21 0.21 R3.0 0.40 0.09 ● EPHW type insert (mm) Corner radius forprogrammingOver cut Remains R1.0 0 0.42 R1.5 (Recommended) 0 0.33 R2.0 0.01 0.23 R2.5 0.17 0.14 R3.0 0.37 0.05 ■ Guidelines for selection of the EP** type insert Carbon steel Die steel Mold steel Moldsteel Work Materials S50C, S55C(C50, C55) SKD61, SKD11 HPM7, PX5, P20 NAK80,HPM1,P21(1.2344, 1.2379)(1.2311, P20)(1.2311,P21) Below 250HB Below 255HB 30-36HRC 38-43HRC Grades Cat. No. JC5118 JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 EPMT100312ZER ☆ ☆ ☆ ☆ ☆ ☆ ☆ ☆ ☆ ☆ ☆ EPMW100312ZER ○ EPMW100312ZTR ○ ○ ◎ ○ ○ ◎ ○ ○ ◎ ○ ◎ EPHW100316ZTR ○ Hardened die steel Hardened die steel Grey & NodularcastironWork MaterialsSKD61, DAC, DHA(1.2344, 1.2379)SKD11, SLD, DC11(1.2344, 1.2379)42-52HRC55-62HRCFC, FCD(GG, GGG)Below 300HBStainless steelSUS304Below 250HB GradesCat. No.JC5118JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 JC5118 JC8050 JC7560 DH102 EPMT100312ZER ☆ × × ○ ○ ◎ EPMW100312ZER ○ ○ ◎ ● EPMW100312ZTR ● ● ● ○ EPHW100316ZTR ◎ ◎ ・EPMW type: Without chip breaker・EPMT type: With chip breaker WorkMaterials Titanium alloyTi-6AI-4V InconelINCO718 ・EPHW type: Without chip breaker ◎: First Choice, Good Condition ○: Moderate Condition GradesCat. No.JC5118JC8050JC7560 DH102 JC5118 JC8050 JC7560 DH102 ●: Unfavorable Condition ☆: Light Cutting ×: No good EPMT100312ZER ○ ○ ◎ ◎ ○ ○ EPMW100312ZER ● ● EPMW100312ZTR EPHW100316ZTR B075

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском