Каталог YG-1 инструментальная оснастка - страница 94

Навигация

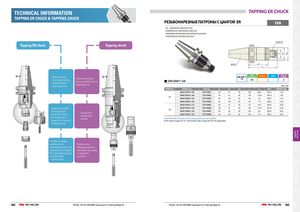

D D1 D2 HydraulicShrink FitER ColletEnd Mill HolderShell MillPower MillingMorse TaperSK SlimSynchroTappingTappingFace MillNC Drill ChuckBoringAccessory ChuckHolderChuck& Side Lock ArborArborChuckArborChuckTapping ChuckER ChuckChuckArbor& Other Tool HoldersSystem& Others A A TECHNICAL INFORMATION TAPPING ER CHUCK TAPPING ER CHUCK & TAPPING CHUCK РЕЗЬБОНАРЕЗНЫЕ ПАТРОНЫ С ЦАНГОЙ ER TER ER - GEWINDESCHNEIDFUTTER MANDRIN DE TARAUDAGE PINCE ER MANDRINI PORTAPINZA ER PER MASCHIATURA PORTAPINZAS ER PARA MACHOS SLEEVE Tapping ER chuck Tapping chuck BODY L1 L Minimizing toolinterference duringmachining withshort gauge lineInterfered with toolduring machining due tolong gauge line TaperDIN 69871AccuracyG ValueRPM CoolantSystem■ DIN 69871-SK- SKAT3--AUnit : mm TAPER No. MODEL No. EDP No. D D1 D2 L L1 NUT WEIGHT (Kg) SK40-TER16-100 P2774001 28 41 45 100 68.4 ER16 1.65 SK40-TER16-150 P2774002 28 41 45 150 118.4 ER16 1.85 40 SK40-TER32-130 P2774003 50 58 63 130 92 ER32 2.10 SK40-TER32-150 P2774004 50 58 63 150 112 ER32 2.30 SK50-TER16-115 P2774005 28 41 45 115 79.4 ER16 4.30 Combining strength SK50-TER16-150 P2774006 28 41 45 150 114.4 ER16 4.5050 of strong torquepower of ER chuckand tension andcompression functionTension andcompressionfunction SK50-TER32-120 P2774007 50 58 63 120 83 ER32 4.65SK50-TER32-150P2774008505863150113ER324.85▶ CAT(ANSI B5.50) taper and Inch type products area available.▶ ER collet of page 95~97, and Tap ER collet of page 98~99 are applicable. of tapping chuck Possible to change suitable tap for Preparing and machining conditions by changing expensive replacement of cheaper tap adapter according ER collet (Sharing collet to machining with ER chuck) conditions -> Saving costs 182 Phone: +82-32-526-0909, www.yg1.kr, E-mail: yg1@yg1.kr Phone: +82-32-526-0909, www.yg1.kr, E-mail: yg1@yg1.kr 183

Каталог YG-1 твердосплавные борфрезы

Каталог YG-1 твердосплавные борфрезы Каталог YG-1 резьбонарезной инструмент

Каталог YG-1 резьбонарезной инструмент Каталог YG-1 фрезерование

Каталог YG-1 фрезерование Каталог YG-1 сверлильный инструмент

Каталог YG-1 сверлильный инструмент Каталог YG-1 сменные пластины

Каталог YG-1 сменные пластины