Общий каталог Winstar 2015 - 2016 - страница 156

Навигация

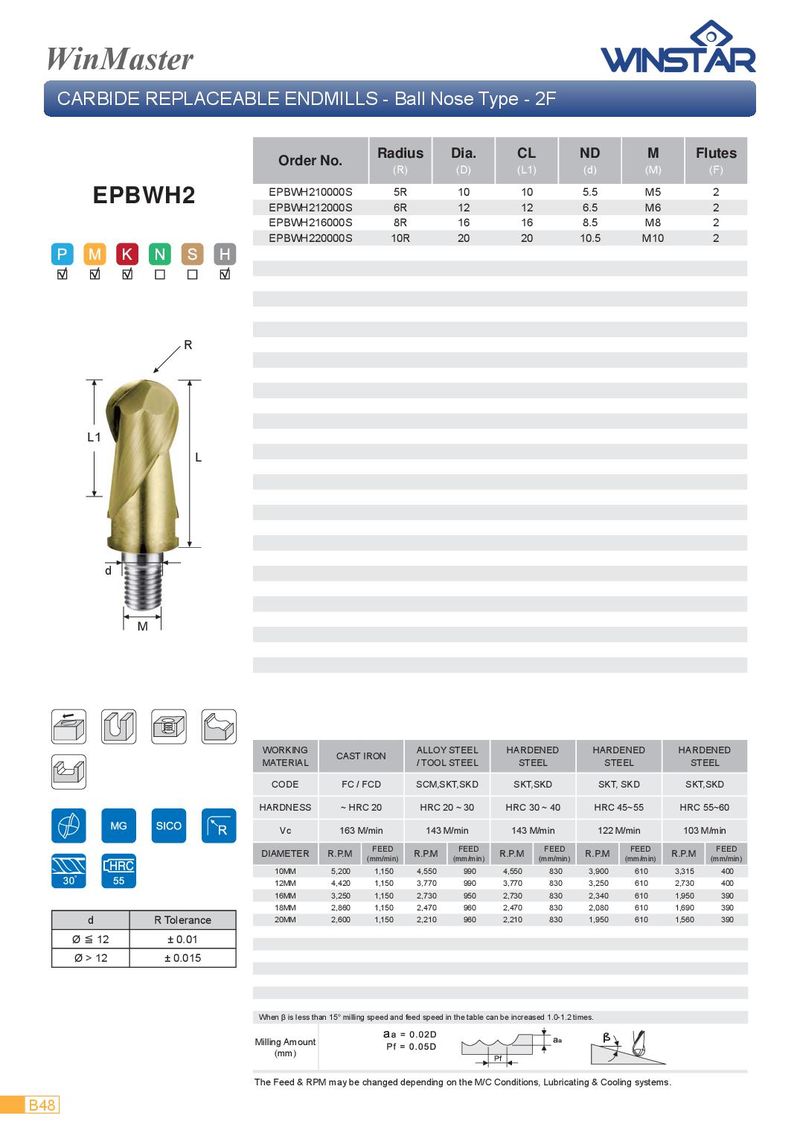

WinMaster CARBIDE REPLACEABLE ENDMILLS - Ball Nose Type - 2F Radius Dia. CL ND M Flutes Order No. (R) (D) (L1) (d) (M) (F) EPBWH210000S 5R 10 10 5.5 M5 2 EPBWH2 EPBWH212000S 6R 12 12 6.5 M6 2 EPBWH216000S 8R 16 16 8.5 M8 2 EPBWH220000S 10R 20 20 10.5 M10 2 R L1 L d M WORKING ALLOY STEEL HARDENED HARDENED HARDENED CAST IRON MATERIAL / TOOL STEEL STEEL STEEL STEEL CODE FC / FCD SCM,SKT,SKD SKT,SKD SKT, SKD SKT,SKD HARDNESS ~ HRC 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 45~55 HRC 55~60 Vc 163 M/min 143 M/min 143 M/min 122 M/min 103 M/min FEED FEED FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 10MM 5,200 1,150 4,550 990 4,550 830 3,900 610 3,315 400 12MM 4,420 1,150 3,770 990 3,770 830 3,250 610 2,730 400 16MM 3,250 1,150 2,730 950 2,730 830 2,340 610 1,950 390 18MM 2,860 1,150 2,470 960 2,470 830 2,080 610 1,690 390 d R Tolerance 20MM 2,600 1,150 2,210 960 2,210 830 1,950 610 1,560 390 Ø ≦ 12 ± 0.01 Ø > 12 ± 0.015 When β is less than 15° milling speed and feed speed in the table can be increased 1.0-1.2 times. Milling Amount (mm) The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. B48

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021