Каталог Winstar монолитный инструмент 2020 - страница 350

Навигация

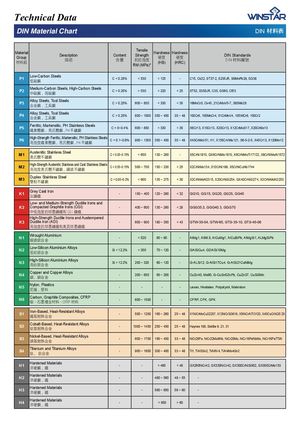

Technical Data DIN Material Chart DIN 㣟㜨姷 MaterialGroup㣟㜨仓 Description㕞慿 Content►捞 TensileStrength㐦㑘テ〵RM (MPa)*Hardness䧻〵(HB)Hardness䧻〵(HRC)DIN StandardsEJO 㣟㜨佷埮 P1 Low-Carbon Steels⃝䩂撋 C < 0.25% < 530 < 125 - C15, Ck22, ST37-2, S235JR, 9SMnPb28, GS38 P2 Medium-Carbon Steels, High-Carbon Steelsᾼ䩂撋 - 汧䩂撋 C > 0.25% > 530 < 220 < 25 ST52, S355JR, C35, GS60, Cf53 P3 Alloy Steels, Tool Steels▗捠撋 - ⽴⌆撋 C > 0.25% 600 ~ 850 < 330 < 35 16MnCr5, Ck45, 21CrMoV5-7, 38SMn28 P4 Alloy Steels, Tool Steels▗捠撋 - ⽴⌆撋 C > 0.25% 800 ~ 1000 350 ~ 450 35 ~ 48 100Cr6, 105MnCr4, 51CrMnV4, 105WCr6, 100Cr2 P5 Ferritic, Martensitic, PH Stainless Steels旄亯汣撋 - 欻㶞汣撋 -QI ᾜ斌撋 C = 0~0.4% 600 ~ 850 < 330 < 35 X6Cr13, X10Cr13, X20Cr13, X12CrMoS17, X20CrMo13 P6 High-Strength Ferritic, Martensitic, PH Stainless Steels汧テ〵旄亯汣撋 - 欻㶞汣撋 -QI ᾜ斌撋C = 0.1~0.6%900 ~ 1350350 ~ 45035 ~ 48X40CrMoV51, H1, X155CrVMo121, S6-5-2-5, X45Cr13, X120Mn12 M1 Austenitic Stainless Steel⫶㶞汣ᾜ斌撋 C = 0.05~0.15% < 650 130 ~ 200 - X5CrNi1810, GX6CrNiMo1810, X6CrNiMoTi17122, X8CrNiMoAl1572 M2 High-Strength Austenitic Stainless and Cast Stainless Steels汧テ〵⫶㶞汣ᾜ斌撋 - 旓憯ᾜ斌撋C = 0.05~0.15%500 ~ 700150 ~ 230< 25X2CrNiMo134, X10CrNi189, X5CrNiCuNb1744 M3 Duplex Stainless Steel桨䢇ᾜ斌撋 C = 0.05~0.2% < 900 135 ~ 275 < 30 X2CrNiMoN2315, X20CrNiSi254, GX40CrNiSi274, X2CrNiMoN2253 K1 Grey Cast Iron䇿旓旄 - 150 ~ 400 120 ~ 290 < 32 GG10, GG15, GG20, GG25, GG40 Low- and Medium-Strength Ductile Irons and K2 Compacted Graphite Irons (CGI) - 400 ~ 600 130 ~ 260 < 28 GGG35.3, GGG40.3, GGG70 ᾼ⃝テ〵䠓䖒⨷旓旄☛ DHJ 旓旄 High-Strength Ductile Irons and Austempered K3 Ductile Iron (ADI) - 600 ~ 900 180 ~ 350 < 43 GTW-35-04, GTW-65, GTS-35-10, GTS-45-06 汧テ〵䠓䖒⨷旓旄☛⫶帬䖒⨷旓旄 N1 Wrought Aluminium擪憯摐▗捠 - < 520 60 ~ 90 - AIMg1, AI99.5, AICuMg1, AICuBiPb, AIMgSi1, ALMgSiPb N2 Low-Silicon Aluminium Alloys⃝䧔摐▗捠 Si < 12.2% < 350 70 ~ 120 - GAISiCu4, GDAISi10Mg N3 High-Silicon Aluminium Alloys汧䧔摐▗捠 Si > 12.2% 200 ~ 320 60 ~ 120 - G-ALSi12, G-AlSi17Cu4, G-AISi21CuNiMg N4 Copper and Copper Alloys搔 - 搔▗捠 - 200 ~ 650 60 ~ 200 - CuZn40, Ms60, G-CuSn5ZnPb, CuZn37, CuSi3Mn N5 Nylon, Plasticsⷋ焜 - ⧠㜨 - - - - Lexan, Hostalen, Polystyrol, Makrolon N6 Carbon, Graphite Composites, CFRP䩂ҷ䦂⨷媖▗㣟㜨ҷDGSQ 㣟㜨 - 600 ~ 1500 - - CFRP, CFK, GFK S1 Iron-Based, Heat-Resistant Alloys旄⦉冟䍀▗捠 - 500 ~ 1200 160 ~ 260 25 ~ 48 X1NiCrMoCu32287, X12NiCrSi3616, X5NiCrAITi3120, X40CoCrNi20 20 S2 Cobalt-Based, Heat-Resistant Alloys揆⦉冟䍀▗捠 - 1000 ~ 1450 250 ~ 450 25 ~ 48 Haynes 188, Stellite 6, 21, 31 S3 Nickel-Based, Heat-Resistant Alloys敂⦉冟䍀▗捠 - 600 ~ 1700 160 ~ 450 33 ~ 48 NiCr29Fe, NiCr22Mo9Nb, NiCr20Mo, NiCr19FeNbMo, NiCr16Fe7TiAl S4 Titanium and Titanium Alloys掵 -!掵▗捠 - 900 ~ 1600 300 ~ 400 33 ~ 48 Ti1, TiAI5Sn2, TiAI6V4, TiAI4Mo4Sn2 H1 Hardened Materials㽻䧻撋 - 旄 - - < 460 < 48 GX260NiCr42, GX330NiCr42, GX300CrNiSi952, GX300CrMo153 H2 Hardened Materials㽻䧻撋 - 旄 - - 460 ~ 560 48 ~ 55 - H3 Hardened Materials㽻䧻撋 - 旄 - - 560 ~ 650 56 ~ 60 - H4 Hardened Materials㽻䧻撋 - 旄 - - > 650 > 60 -

Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar сверление

Каталог Winstar сверление Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021