Каталог Winstar монолитный инструмент 2020 - страница 232

Навигация

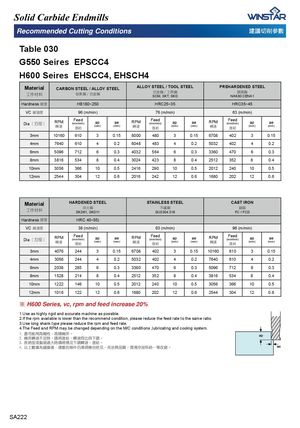

Solid Carbide Endmills Recommended Cutting Conditions ら峿⎖⏙╒㜇 Table 030 G550 Seires EPSCC4 H600 Seires EHSCC4, EHSCH4 Material CARBON STEEL / ALLOY STEEL ALLOY STEEL / TOOL STEEL PREHARDENED STEEL ⽴₅㣟㜨 䩂亯撋 0 ▗捠撋 ▗捠撋 0 ⽴⌆撋SCM, SKT, SKD 屎幹撋NAK80 CENA1 Hardness 䧻〵 HB180~250 HRC25~35 HRC35~45 VC 佩憮〵 96 (m/min) 76 (m/min) 63 (m/min) Dia ) ⎒ㄠ * RPM 惘憮 Feed (mm/min)懁仵 ap(mm) ae RPM Feed (mm/min) ap(mm)惘憮懁仵(mm)ae RPM Feed (mm/min) ap(mm)惘憮懁仵(mm)ae(mm) 3mm 10160 610 3 0.15 8000 480 3 0.15 6708 402 3 0.15 4mm 7640 610 4 0.2 6048 483 4 0.2 5032 402 4 0.2 6mm 5096 712 6 0.3 4032 564 6 0.3 3360 470 6 0.3 8mm 3816 534 8 0.4 3024 423 8 0.4 2512 352 8 0.4 10mm 3056 366 10 0.5 2416 290 10 0.5 2012 240 10 0.5 12mm 2544 304 12 0.6 2016 242 12 0.6 1680 202 12 0.6 Material HARDENED STEEL STAINLESS STEEL CAST IRON ⽴₅㣟㜨 㽻䇺撋SKD61, SKD11 ᾜ斌撋SUS304 316 旓旄FC / FCD Hardness 䧻〵 HRC 40~55) VC 佩憮〵 38 (m/min) 63 (m/min) 96 (m/min) Dia ) ⎒ㄠ * RPM 惘憮 Feed (mm/min)懁仵 ap(mm) ae RPM Feed (mm/min) ap(mm)惘憮懁仵(mm)ae RPM Feed (mm/min) ap(mm)惘憮懁仵(mm)ae(mm) 3mm 4076 244 3 0.15 6708 402 3 0.15 10160 610 3 0.15 4mm 3056 244 4 0.2 5032 402 4 0.2 7640 610 4 0.2 6mm 2038 285 6 0.3 3360 470 6 0.3 5096 712 6 0.3 8mm 1528 214 8 0.4 2512 352 8 0.4 3816 534 8 0.4 10mm 1222 146 10 0.5 2012 240 10 0.5 3056 366 10 0.5 12mm 1016 122 12 0.6 1680 202 12 0.6 2544 304 12 0.6 ʰ H600 Series, vc, rpm and feed increase 20% 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. 2/ 䡰╾劌䚷汧⏪ㆶҷ汧乍㯮〙Ҹ 3/ 㯮〙惘憮ᾜ彂㟑虇屚ⶖ懁仵ҷ惘憮▛㵣ℚᾚ屎Ҹ 4/ 朆㥓⤚㎥⇞㚉懝⪶㟑屚嬥㉔㹐ᾚ屎惘憮ҷ懁仵Ҹ 5/ ⁴ᾙ㜇㙩䉉ら峿⇋虇懸䜅䠓㨬₅⁜榗嬥㯮╿䑏㹐ҷ⫍㹊⌆♐幹ҷ䃳䁠⍆┊亊伀ʫ䳘㛈崙Ҹ SA222

Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar сверление

Каталог Winstar сверление Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021