Каталог TooTool техническая информация 2 - страница 196

Навигация

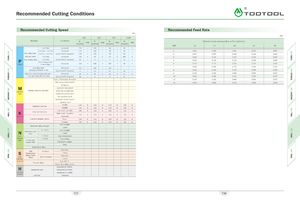

Recommended Cutting Conditions A\ Recommended Cutting Speed Recommended Feed Rate mm mm 3xD 5xD 7xD lOxD Material Condition Vc(m/min)VRR Vc(m/min)VRR Vc(m/min)VRR Vc(m/min)VRR Diameter (mm) corresponding to feed (mm/rev) VRR 12 15 20 25 40 <0.25%C Annealed 110 7 100 7 100 7 90 7 >0.25%C...< 0.55% Annealed 110 7 100 7 100 7 90 7 2 0.052 0.058 0.067 0.075 0.094 Non-alloy steel <0.25%...< 0.55%C Quenched & Tempered 100 7 100 7 100 7 80 7 3 0.077 0.087 0.100 0.110 0.140 and cast steel, >0.55%C Annealed 100 6 90 6 90 6 880 6 4 0.100 0.120 0.130 0.150 0.190 P free cutting steel >0.55%CFree cutting steelQuenched & Tempered 80 7 71 7 71 7 63 7 5 0.130 0.140 0.170 0.190 0.240 PSteel (short chips) Annealed 110 7 100 7 100 7 90 7 6 0.150 0.170 0.200 0.220 0.280 Low alloy steel Annealed 110 7 100 7 100 7 7 0.180 0.200 0.230 0.260 0.330 (alloying elements < 5%) Quenched 8t Tempered 71 7 63 7 63 7 56 7 8 0.210 0.230 0.270 0.300 0.380 High alloy steel (alloying elements > Annealed 80 6 80 6 80 6 63 6 9 0.230 0.260 0.300 0.340 0.420 5%), cast steel, and tool steel Quenched & Tempered 80 7 71 7 71 7 63 7 10 0.260 0.290 0.330 0.370 0.470 Ferric / Martensitic Annealed 12 0.310 0.350 0.400 0.450 0.570 Martensitic Quenched & 16 0.410 0.460 0.530 0.600 0.750 Tempered M Austenitic Quenched stainless Stainless steel & Cast steel Austenitic precipitation steel hardened stainless steel (PH stainless steel) Austenitic-ferritic duplex stainless steel Ferritic 110 8 110 8 110 8 100 8 Malleable cast iron Pearlitic 110 8 110 8 110 8 100 8 K Grey cast iron (GG) Low tensile strength 140 9 140 9 120 9 120 9High tensile strength/1209120912091109 Cast iron Austenitic Cast iron Nodular (GGG) Ferric 120 8 120 8 120 8 110 8 Pearlitic 110 8 110 8 110 8 100 8 Not cureable Aluminum alloy wrought Cured < 12% SiNAluminum-castalloyNot cureableCured Non- > 12% Si High temperature ferrous > 1% Pb Free cutting alloy Copper and cooper alloy Electrolytic Copper Brass Magnesium alloy Annealed s HighTemperature. Fe based Cured Alloys, Super Annealed Heat Alloys Ni or Co basedresistant Cured material Pure 99.5 Ti Titanium Alloy Alpha+Beta Alloys Cured H Hardened steel Hardened 45-50HRCHardened 51-55HRC Hardened Hardened 52-62HRC material Cast iron Hardened 747 748

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы