Каталог TooTool техническая информация 2 - страница 178

Навигация

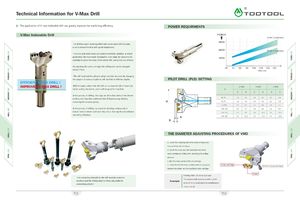

Technical Information for V-Max Drill A\ The application of V-max indexable drill can greatly improve the machining efficiency. POWER REQUIRMENTS V-Max Indexable Drill POWER t fn=0.2 (mm/rev) 30KW •The drill has good centering effect with center pilot drill structure, so as to ensure the hole with good straightness. 20KW fn=0.1 (mm/rev) The inner and outer edges are used in insertable cartridge. In actual application, the most easily damaged is outer edge, by replacing the 10KW cartridge to avoid the scrap of the whole drill, saving the cost of tools. If i •By adjusting the outer cartridge, the drilling size can be changedwithin 0-5mm•The drill head and the adoptor adopt modular structure. By changing 7>00406080100120140160DRILL DIA the adoptor of various lengths to drill the hole of different depths. PILOT DRILL (PLD) SETTING EFFICIEN MX DRILL ! IMPROVE -MAX DRILL ! With through coolant hole, the drill can increase the life of inserts by 2-4XD 4-6XD 6-8XD better cooling the inserts ,also it will be good for chip flow. 5)V D A B A B A B In the process of drilling, the chips are all broken, without the slenderwinding iron chips like traditional twist drill processing, therebyimproving the security greatly.L~ 45- 55 1.6 4.0 1.8 4.2 2.0 4.4omXvV55-751.85.42.05.62.25.8 75-100 2.2 6.5 2.5 6.8 2.8 7.1 •In the process of drilling, by automatic feeding continuously, it 100-120 2.4 7.7 2.8 8.1 3.2 8.5 doesn't need to return back each chip off, so that significantly enhance 120-170 3.2 9.9 3.6 10.3 4.0 10.7 machining efficiency. A 170-180 3.5 12.2 3.9 12.6 4.3 13.0 B THE DIAMETER ADJUSTING PROCEDURES OF VMD 1. Loosen the clamping bolt of the outer cartridge and remove it from the drill body. 2. Cut off the inside part, the contacted side of the outer cartridge by milling after calculating the drilling diameter. 3. Slick the sharp corner of the cut cartridge. 4. Clamp the bolt for fixing cartridge without any gap in | Outer cartridge |- | Bolt for fixing cartridge | between the holder and the machined outer cartridge. If setting VMD-135140 to 0136 seat The connecting strength by the drill modular system is The standard drill diameter is 0140 so 0140- excellent and the drilling depth is freely adjustable by Example connecting adoptor 0136=4—>4+2=2(calculation by semidiameter) 2mm is cut off. 711 712

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы