Общий каталог Sumitomo 2019 - 2020 - страница 787

Навигация

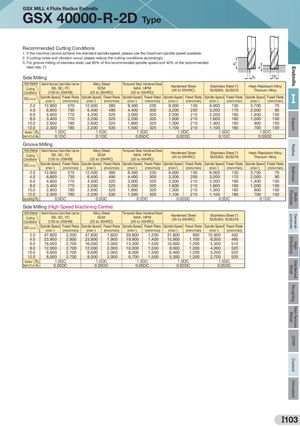

ap ap UncoatedCoatedCFRPNon-ferrousMetalRoughingHardenedSteelHighEfficiencyGeneral-purposeMulti-PurposeBallnoseRadiusSquareEndmills GSX MILL 4 Flute Radius Endmills GSX 40000-R-2D Type Recommended Cutting Conditions 1. If the machine cannot achieve the standard spindle speed, please use the maximum spindle speed available. 2. If cutting noise and vibration occur, please reduce the cutting conditions accordingly. 3. For groove milling of stainless steel, use 60% of the recommended spindle speed and 40% of the recommended feed rate. (*) Side Milling ae DC Work Material Steel for Structure, Carbon Steel, Cast IronCuttingSS, SC, FCConditions(150 to 250HB)Alloy SteelSCM(25 to 35HRC)Tempered Steel, Hardened SteelNAK, HPM(35 to 45HRC)Hardened Steel(45 to 55HRC)Stainless Steel (*)Heat-Resistant AlloySUS304, SUS316Titanium Alloy DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate(min-1)(mm/min)(min-1)(mm/min)(min-1)(mm/min)(min-1)(mm/min)(min-1)(mm/min)(min-1)(mm/min)I 2.0 12,800 570 12,000 380 8,300 230 6,000 150 6,000 130 3,700 70 4.0 6,800 730 6,400 490 4,400 300 3,200 200 3,200 170 2,000 90 6.0 4,600 770 4,300 520 3,000 320 2,200 210 2,200 180 1,400 100 8.0 3,400 770 3,200 520 2,200 320 1,600 210 1,600 180 1,000 100 10.0 2,800 780 2,600 520 1,800 320 1,300 210 1,300 180 800 100 12.0 2,300 780 2,200 530 1,500 320 1,100 210 1,100 180 700 100 Standard ap 1.5DC 1.5DC 1.5DC 1.0DC 1.5DC 1.0DC Depth of Cut ae 0.1DC 0.1DC 0.05DC 0.02DC 0.1DC 0.05DC Groove Milling Work Material Steel for Structure, Carbon Steel, Cast IronCuttingSS, SC, FCConditions(150 to 250HB)Alloy SteelSCM(25 to 35HRC)Tempered Steel, Hardened SteelNAK, HPM(35 to 45HRC)Hardened Steel(45 to 55HRC)Stainless Steel (*)Heat-Resistant AlloySUS304, SUS316Titanium Alloy DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 2.0 12,800 570 12,000 380 8,300 230 6,000 150 6,000 130 3,700 70 4.0 6,800 730 6,400 490 4,400 300 3,200 200 3,200 170 2,000 90 6.0 4,600 770 4,300 520 3,000 320 2,200 210 2,200 180 1,400 100 8.0 3,400 770 3,200 520 2,200 320 1,600 210 1,600 180 1,000 100 10.0 2,800 780 2,600 520 1,800 320 1,300 210 1,300 180 800 100 12.0 2,300 780 2,200 530 1,500 320 1,100 210 1,100 180 700 100 Groove Mil ing ap 0.5DC 0.5DC 0.2DC 0.05DC 0.3DC 0.1DC Side Milling (High Speed Machining Centre) Work Material Steel for Structure, Carbon Steel, Cast IronCuttingSS, SC, FCConditions(150 to 250HB)Alloy SteelSCM(25 to 35HRC)Tempered Steel, Hardened SteelNAK, HPM(35 to 45HRC)Hardened Steel(45 to 55HRC)Stainless Steel (*)SUS304, SUS316 DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 2.0 47,800 2,200 47,800 1,600 39,800 1,200 31,800 900 15,900 400 4.0 23,900 2,600 23,900 1,900 19,900 1,400 15,900 1,100 8,000 490 6.0 16,000 2,700 16,000 2,000 13,300 1,500 10,600 1,200 5,300 510 8.0 12,000 2,700 12,000 2,000 10,000 1,500 8,000 1,200 4,000 520 10.0 9,600 2,700 9,600 2,000 8,000 1,500 6,400 1,200 3,200 520 12.0 8,000 2,700 8,000 2,000 6,700 1,500 5,300 1,200 2,700 520 Standard ap 1.5DC 1.5DC 1.5DC 1.0DC 1.5DC Depth of Cut ae 0.05DC 0.05DC 0.05DC 0.02DC 0.05DC I103

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019