Общий каталог Sumitomo 2019 - 2020 - страница 1111

Навигация

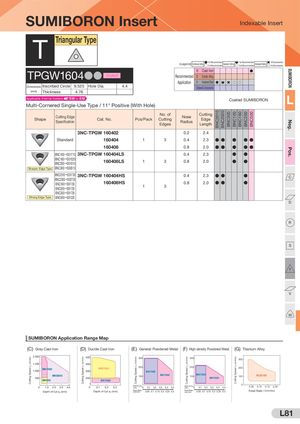

Cutting Speed vc (m/min) Cutting Speed vc (m/min) Cutting Speed vc (m/min) Cutting Speed vc (m/min) BNC2010 BNC2020 BNC300 BNC100 Cutting Speed vc (m/min) BNC160 BNC200 BNC500 Pos.Neg.SUMIBORON SUMIBORON Insert Indexable Insert T Triangular Type (Legend) Continuous Cutting : 1st Recommended : 2nd Recommended General Cutting : 1st Recommended: 2nd RecommendedInterrupted Cutting: 1st Recommended: 2nd Recommended TPGW1604●● Coated K Cast IronRecommendedSExotic Alloy Application H Hardened Steel Dimensions Inscribed Circle 9.525 Hole Dia. 4.4 Sintered Components (mm) Thickness 4.76 Applicable Internal Holders E50 to E52 Coated SUMIBORON L Multi-Cornered Single-Use Type / 11° Positive (With Hole) Shape Cutting EdgeSpecification Cat. No. No. ofPcs/PackCuttingEdgesNoseRadius CuttingEdgeLength 3NC-TPGW 160402 0.2 2.4 Standard 160404 1 3 0.4 2.3 ●● ● ●● 160408 0.8 2.0 ●● ● ●● BNC100→S01715 3NC-TPGW 160404LS 0.4 2.3 ● ● BNC160→S01020BNC200→S01015 160408LS 1 3 0.8 2.0 ● ● Sharper Edge Type BNC300→S00515 BNC2010→S01730 3NC-TPGW 160404HSBNC2020→S02735 0.4 2.3 ●● ● C BNC160→S01730BNC200→S01735 160408HS 0.8 2.0 ●● ●13 BNC300→S01735 Strong Edge Type BNC500→S01225 D R S T V W SUMIBORON Application Range Map (C) Gray Cast Iron (D) Ductile Cast Iron (E) General Powdered Metal (F) High-density Powdered Metal (G) Titanium Alloy 2,000 500 300 300 300 1,500 400 BN7000 BNC500 200 200 200 1,000 300 BN7500 BNS800500 200 100 BN7000 BN7500100 BN7000 100 NCB100 BN500 BN7000 0 1.0 2.0 3.0 4.0 0 0.1 0.3 0.5 Depth (mm)of Cut ap 0 0.1 0.2 0.3 0.4 0.5 Depth (mm)of Cut ap 0 0.1 0.2 0.3 0.4 0.5 0 0.05 0.10 0.15 0.20 Depth of Cut ap (mm) Depth of Cut ap (mm) Feed Rate f(mm/rev) 0.05 0.1 0.15 0.2 0.25 0.3 Feed Rate f(mm/rev) 0.05 0.1 0.15 0.2 0.25 0.3 Feed Rate f (mm/rev) L81

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019