Каталог Sumitomo твердосплавные заготовки - страница 9

Навигация

Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент

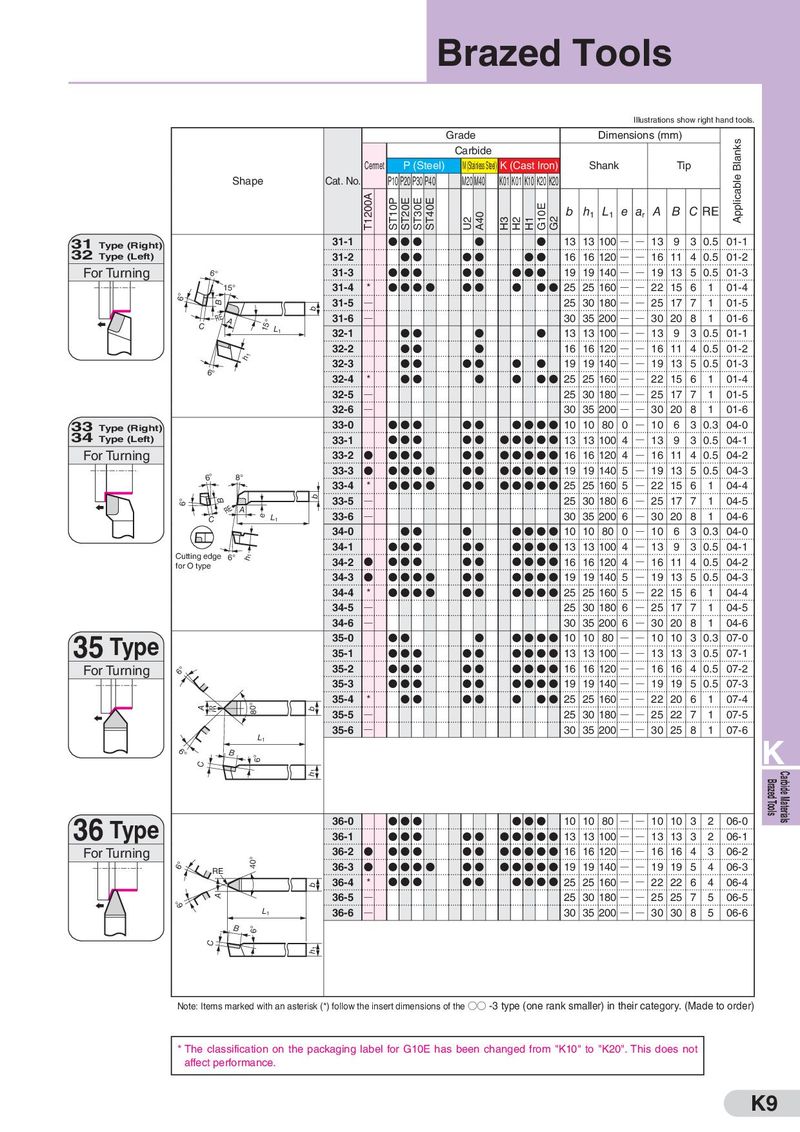

Brazed Tools Illustrations show right hand tools. Grade Dimensions (mm) Applicable Blanks Carbide Cermet P (Steel) M (Stainless Steel) K (Cast Iron) Shank Tip Shape Cat. No. P10 P20 P30 P40 M20 M40 K01 K01 K10 K20 K20 T1200A ST10P ST20E ST30E ST40E U2 A40 H3 H2 H1 G10E G2 b h1 L1 e ar A B C RE 31 Type (Right) 31-1 D D D D D 13 13 100 Q Q 13 9 3 0.5 01-1 32 Type (Left) 31-2 D D D D D D 16 16 120 Q Q 16 11 4 0.5 01-2 For Turning 6° 31-3 D D D D D DD D 19 19 140 Q Q 19 13 5 0.5 01-3 15° 31-4 * D D D D D D D D D 25 25 160 Q Q 22 15 6 1 01-4 6° B 31-5 Q 25 30 180 Q Q 25 17 7 1 01-5 b C RE A 15° 31-6 Q 30 35 200 Q Q 30 20 8 1 01-6 L1 32-1 D D D D 13 13 100 Q Q 13 9 3 0.5 01-1 32-2 D D D 16 16 120 Q Q 16 11 4 0.5 01-2 h1 32-3 D D D D D D 19 19 140 Q Q 19 13 5 0.5 01-3 6° 32-4 * D D D D D D 25 25 160 Q Q 22 15 6 1 01-4 32-5 Q 25 30 180 Q Q 25 17 7 1 01-5 32-6 Q 30 35 200 Q Q 30 20 8 1 01-6 33 Type (Right) 33-0 D D D D D D D D D 10 10 80 0 Q 10 6 3 0.3 04-0 34 Type (Left) 33-1 D D D D D D D D D D 13 13 100 4 Q 13 9 3 0.5 04-1 For Turning 33-2 D D D D D D D D D D D 16 16 120 4 Q 16 11 4 0.5 04-2 6° 8° 33-3 D D D D D D D D D D D D 19 19 140 5 Q 19 13 5 0.5 04-3 33-4 * D D D D D D D D D D D 25 25 160 5 Q 22 15 6 1 04-4 6° B b 33-5 Q 25 30 180 6 Q 25 17 7 1 04-5 RE A e 33-6 Q 30 35 200 6 Q 30 20 8 1 04-6 C L1 34-0 D D D D D D D 10 10 80 0 Q 10 6 3 0.3 04-0 34-1 D D D D D D D D D 13 13 100 4 Q 13 9 3 0.5 04-1 Cutting edge 6° h1 34-2 D D D D D D D D D D 16 16 120 4 Q 16 11 4 0.5 04-2 for O type 34-3 D D D D D D D D D D D 19 19 140 5 Q 19 13 5 0.5 04-3 34-4 * D D D D D D D D D D 25 25 160 5 Q 22 15 6 1 04-4 34-5 Q 25 30 180 6 Q 25 17 7 1 04-5 34-6 Q 30 35 200 6 Q 30 20 8 1 04-6 35 Type 35-0 D D D D D D D 10 10 80 Q Q 10 10 3 0.3 07-0 35-1 D D D D D D D D D 13 13 100 Q Q 13 13 3 0.5 07-1 For Turning 6° 35-2 D D D D D D D D D 16 16 120 Q Q 16 16 4 0.5 07-2 35-3 D D D D D D D D D 19 19 140 Q Q 19 19 5 0.5 07-3 80° 35-4 * D D D D D D D 25 25 160 Q Q 22 20 6 1 07-4 A RE b 35-5 25 30 180 25 22 7 1 07-5 Q Q Q L1 35-6 Q 30 35 200 Q Q 30 25 8 1 07-6 6° B 6° K C h1 Carbide Materials Brazed Tools 36 Type 36-0 D D D DDD 10 10 80 Q Q 10 10 3 2 06-0 36-1 D D D DD DDDDD 13 13 100 Q Q 13 13 3 2 06-1 For Turning 40° 36-2 D D D D DD DDDDD 16 16 120 Q Q 16 16 4 3 06-2 6° RE 36-3 D D D DD DD DDDDD 19 19 140 Q Q 19 19 5 4 06-3 b 36-4 * D D D DD DDDD 25 25 160 Q Q 22 22 6 4 06-4 A 36-5 Q 25 30 180 Q Q 25 25 7 5 06-5 6° L1 36-6 Q 30 35 200 Q Q 30 30 8 5 06-6 B 6° C h1 Note: Items marked with an asterisk (*) follow the insert dimensions of the ○○ -3 type (one rank smaller) in their category. (Made to order) * The classification on the packaging label for G10E has been changed from "K10" to "K20". This does not affect performance. K9