Каталог Stellram высокопроизводительные фрезерные системы - страница 86

Навигация

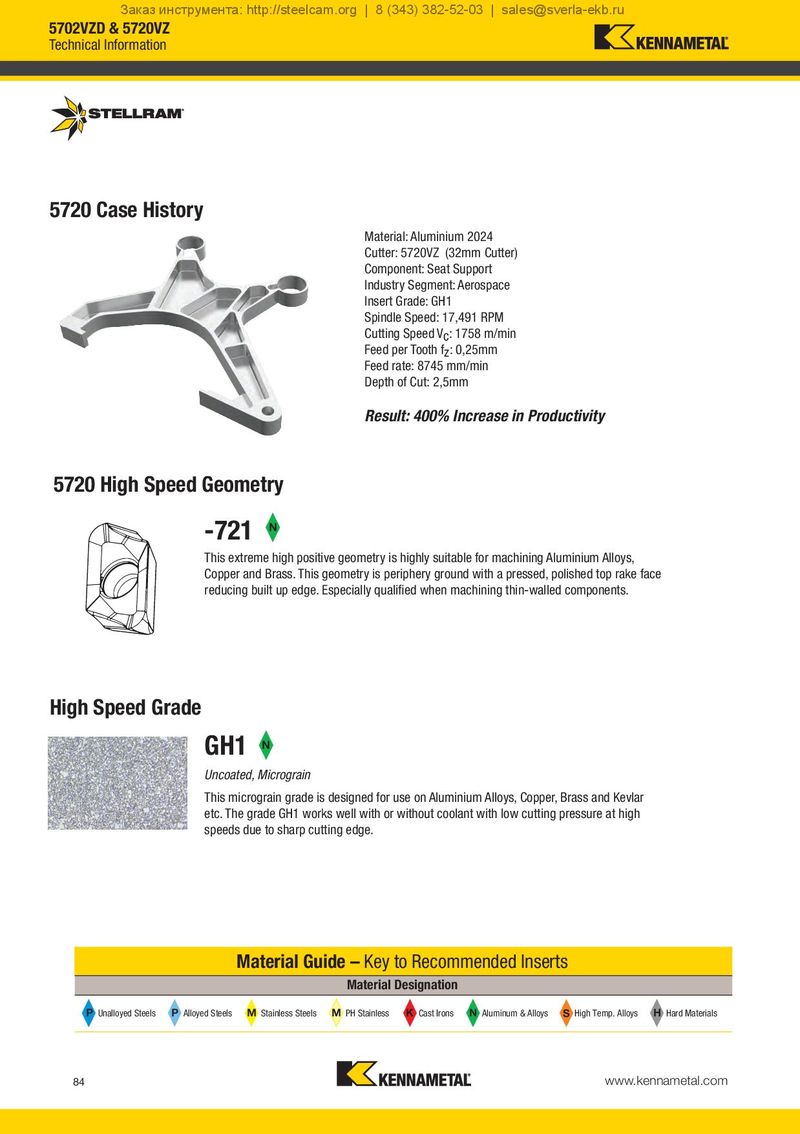

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5702VZD & 5720VZ Technical Information 5720 Case History Material: Aluminium 2024 Cutter: 5720VZ (32mm Cutter) Component: Seat Support Industry Segment: Aerospace Insert Grade: GH1 Spindle Speed: 17,491 RPM Cutting Speed Vc: 1758 m/min Feed per Tooth fz: 0,25mm Feed rate: 8745 mm/min Depth of Cut: 2,5mm Result: 400% Increase in Productivity 5720 High Speed Geometry -721 N This extreme high positive geometry is highly suitable for machining Aluminium Alloys, Copper and Brass. This geometry is periphery ground with a pressed, polished top rake face reducing built up edge. Especially qualified when machining thin-walled components. High Speed Grade GH1 N Uncoated, Micrograin This micrograin grade is designed for use on Aluminium Alloys, Copper, Brass and Kevlar etc. The grade GH1 works well with or without coolant with low cutting pressure at high speeds due to sharp cutting edge. Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials 84 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами