Каталог Stellram высокопроизводительные фрезерные системы - страница 65

Навигация

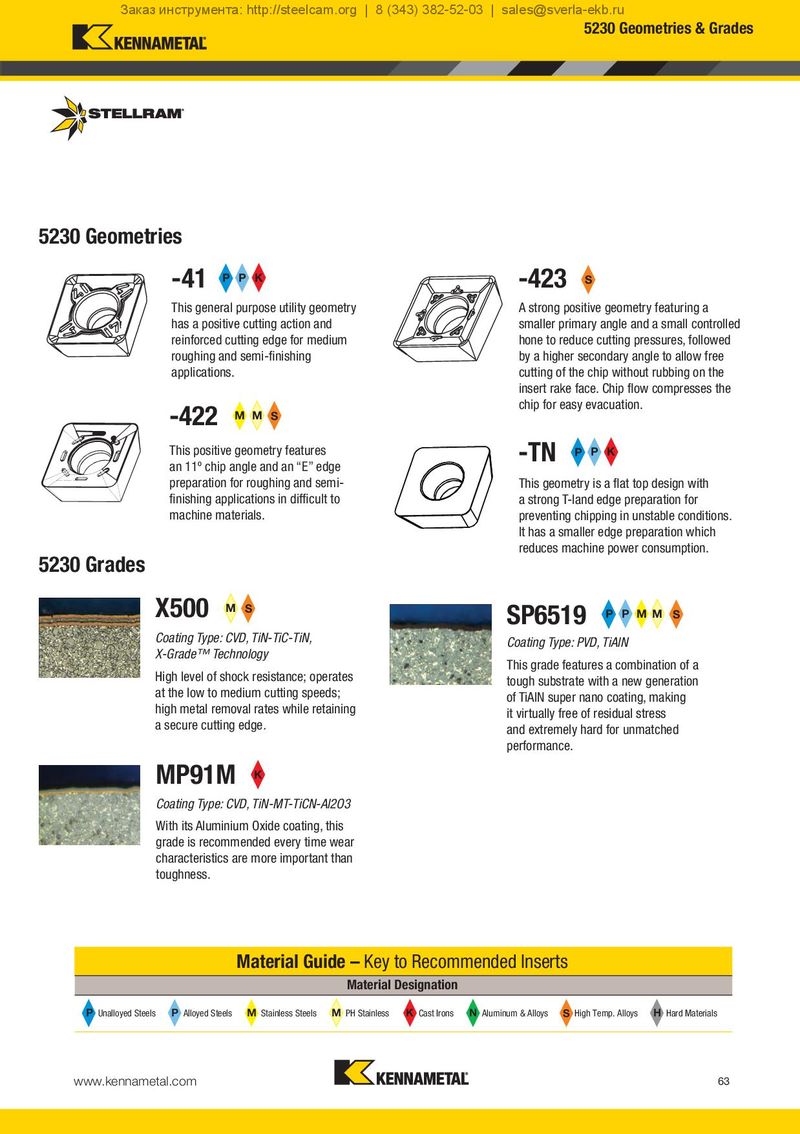

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5230 Geometries & Grades 5230 Geometries -41 P P K -423 S This general purpose utility geometry A strong positive geometry featuring a has a positive cutting action and smaller primary angle and a small controlled reinforced cutting edge for medium hone to reduce cutting pressures, followed roughing and semi-finishing by a higher secondary angle to allow free applications. cutting of the chip without rubbing on the insert rake face. Chip flow compresses the -422 M M chip for easy evacuation. S This positive geometry features -TN P P K an 11º chip angle and an “E” edge preparation for roughing and semi- This geometry is a flat top design with finishing applications in difficult to a strong T-land edge preparation for machine materials. preventing chipping in unstable conditions. It has a smaller edge preparation which reduces machine power consumption. 5230 Grades X500 M S SP6519 P P M M S Coating Type: CVD, TiN-TiC-TiN, Coating Type: PVD, TiAlN X-Grade™ Technology This grade features a combination of a High level of shock resistance; operates tough substrate with a new generation at the low to medium cutting speeds; of TiAlN super nano coating, making high metal removal rates while retaining it virtually free of residual stress a secure cutting edge. and extremely hard for unmatched performance. MP91M K Coating Type: CVD, TiN-MT-TiCN-Al2O3 With its Aluminium Oxide coating, this grade is recommended every time wear characteristics are more important than toughness. Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials www.kennametal.com 63

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами