Каталог Stellram токарный инструмент - страница 208

Навигация

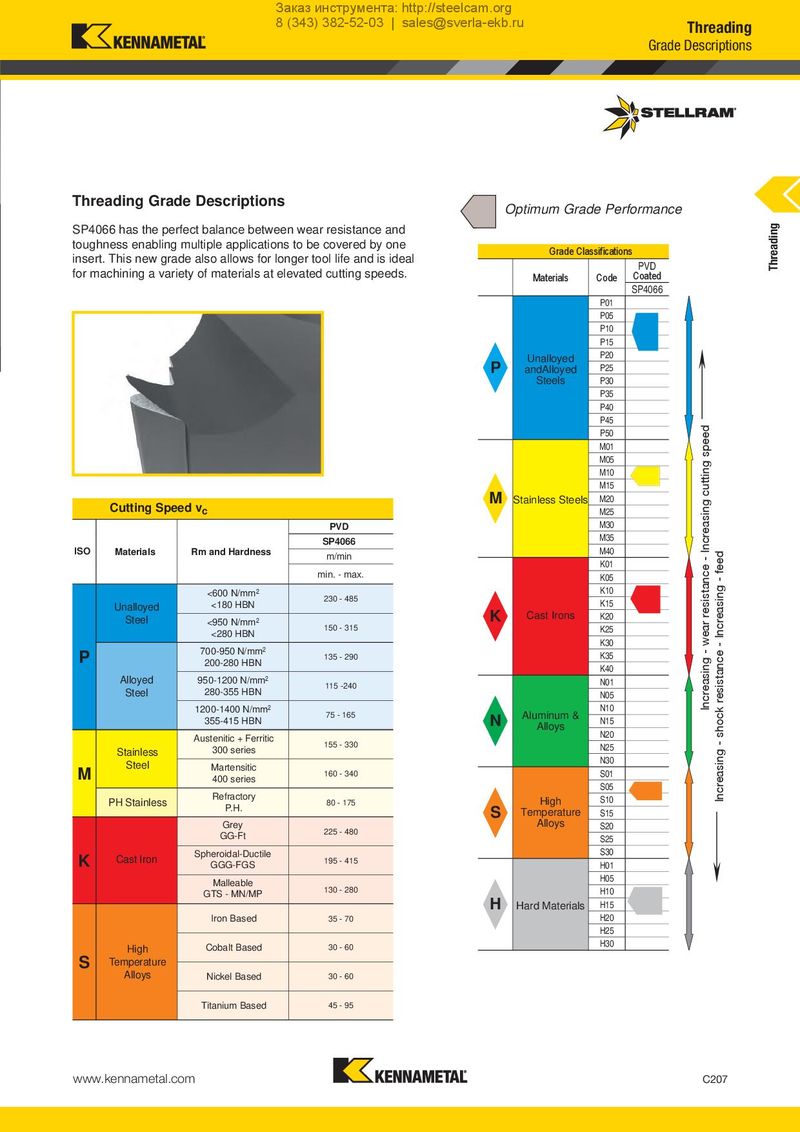

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Threading Grade Descriptions Threading Grade Descriptions Optimum Grade Performance SP4066 has the perfect balance between wear resistance and Threading toughness enabling multiple applications to be covered by one Grade Classifications insert. This new grade also allows for longer tool life and is ideal PVD for machining a variety of materials at elevated cutting speeds. Materials Code Coated SP4066 P01 P05 P10 P15 Unalloyed P20 P andAlloyed P25 Steels P30 P35 P40 P45 Increasing - wear resistance - Increasing cutting speed P50 M01 M05 M10 M15 Cutting Speed vc M Stainless Steels M20 M25 PVD M30 SP4066 M35 ISO Materials Rm and Hardness m/min M40 Increasing - shock resistance - Increasing - feed K01 min. - max. K05 <600 N/mm2 230 - 485 K10 Unalloyed <180 HBN K15 Steel <950 N/mm2 K Cast Irons K20 <280 HBN 150 - 315 K25 700-950 N/mm2 K30 P 200-280 HBN 135 - 290 K35 K40 Alloyed 950-1200 N/mm2 115 -240 N01 Steel 280-355 HBN N05 1200-1400 N/mm2 75 - 165 Aluminum & N10 355-415 HBN N Alloys N15 Austenitic + Ferritic N20 Stainless 300 series 155 - 330 N25 Steel Martensitic N30 M 400 series 160 - 340 S01 S05 PH Stainless Refractory 80 - 175 High S10 P.H. S Temperature S15 Grey Alloys S20 GG-Ft 225 - 480 S25 K Cast Iron Spheroidal-Ductile 195 - 415 S30 GGG-FGS H01 Malleable H05 GTS - MN/MP 130 - 280 H10 H Hard Materials H15 Iron Based 35 - 70 H20 H25 High Cobalt Based 30 - 60 H30 S Temperature Alloys Nickel Based 30 - 60 Titanium Based 45 - 95 www.kennametal.com C207

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами