Каталог Stellram фрез со сменными пластинами - страница 252

Навигация

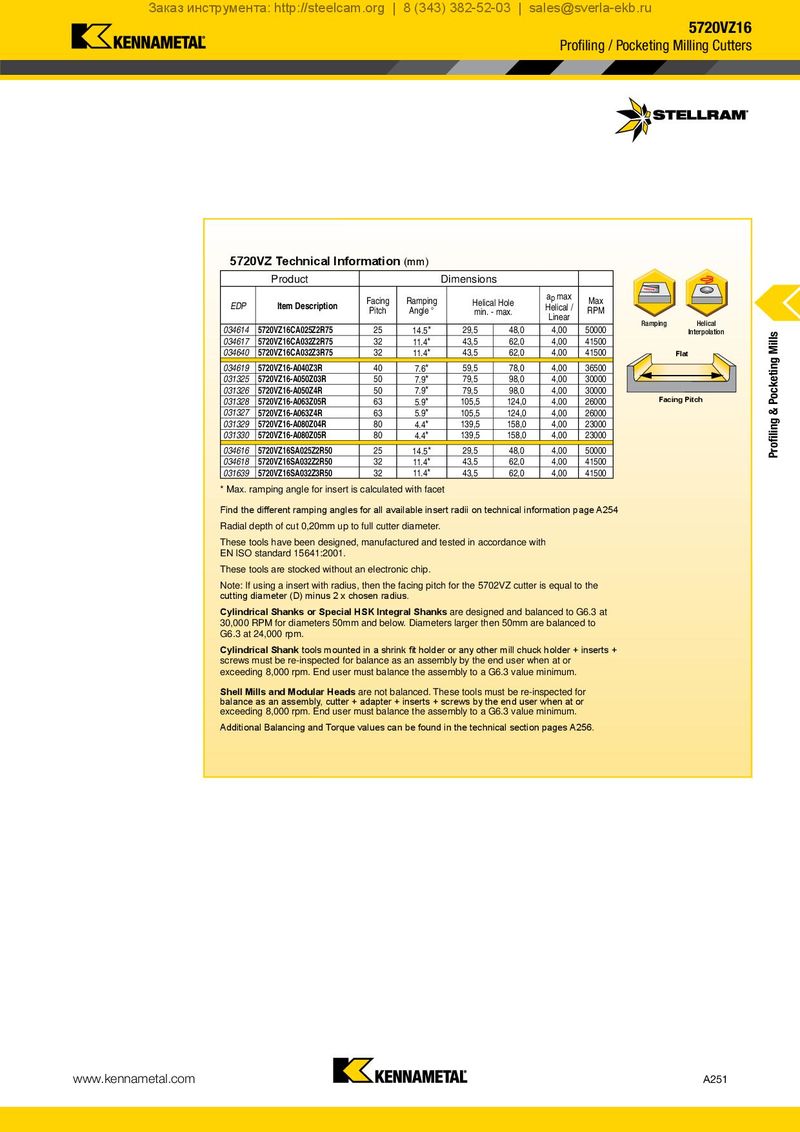

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5720VZ16 Profiling / Pocketing Milling Cutters 5720VZ Technical Information (mm) Product Dimensions EDP Item Description Facing Ramping Helical Hole ap max Max Pitch Angle ° min. - max. Helical / RPM Linear Ramping Helical 034614 5720VZ16CA025Z2R75 25 14.5* 29,5 48,0 4,00 50000 Interpolation Profiling & Pocketing Mills 034617 5720VZ16CA032Z2R75 32 11.4* 43,5 62,0 4,00 41500 034640 5720VZ16CA032Z3R75 32 11.4* 43,5 62,0 4,00 41500 Flat 034619 5720VZ16-A040Z3R 40 7.6* 59,5 78,0 4,00 36500 031325 5720VZ16-A050Z03R 50 7.9* 79,5 98,0 4,00 30000 031326 5720VZ16-A050Z4R 50 7.9* 79,5 98,0 4,00 30000 031328 5720VZ16-A063Z05R 63 5.9* 105,5 124,0 4,00 26000 Facing Pitch 031327 5720VZ16-A063Z4R 63 5.9* 105,5 124,0 4,00 26000 031329 5720VZ16-A080Z04R 80 4.4* 139,5 158,0 4,00 23000 031330 5720VZ16-A080Z05R 80 4.4* 139,5 158,0 4,00 23000 034616 5720VZ16SA025Z2R50 25 14.5* 29,5 48,0 4,00 50000 034618 5720VZ16SA032Z2R50 32 11.4* 43,5 62,0 4,00 41500 031639 5720VZ16SA032Z3R50 32 11.4* 43,5 62,0 4,00 41500 * Max. ramping angle for insert is calculated with facet Find the different ramping angles for all available insert radii on technical information page A254 Radial depth of cut 0,20mm up to full cutter diameter. These tools have been designed, manufactured and tested in accordance with EN ISO standard 15641:2001. These tools are stocked without an electronic chip. Note: If using a insert with radius, then the facing pitch for the 5702VZ cutter is equal to the cutting diameter (D) minus 2 x chosen radius. Cylindrical Shanks or Special HSK Integral Shanks are designed and balanced to G6.3 at 30,000 RPM for diameters 50mm and below. Diameters larger then 50mm are balanced to G6.3 at 24,000 rpm. Cylindrical Shank tools mounted in a shrink fit holder or any other mill chuck holder + inserts + screws must be re-inspected for balance as an assembly by the end user when at or exceeding 8,000 rpm. End user must balance the assembly to a G6.3 value minimum. Shell Mills and Modular Heads are not balanced. These tools must be re-inspected for balance as an assembly, cutter + adapter + inserts + screws by the end user when at or exceeding 8,000 rpm. End user must balance the assembly to a G6.3 value minimum. Additional Balancing and Torque values can be found in the technical section pages A256. www.kennametal.com A251

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы