Каталог Stellram фрез со сменными пластинами - страница 234

Навигация

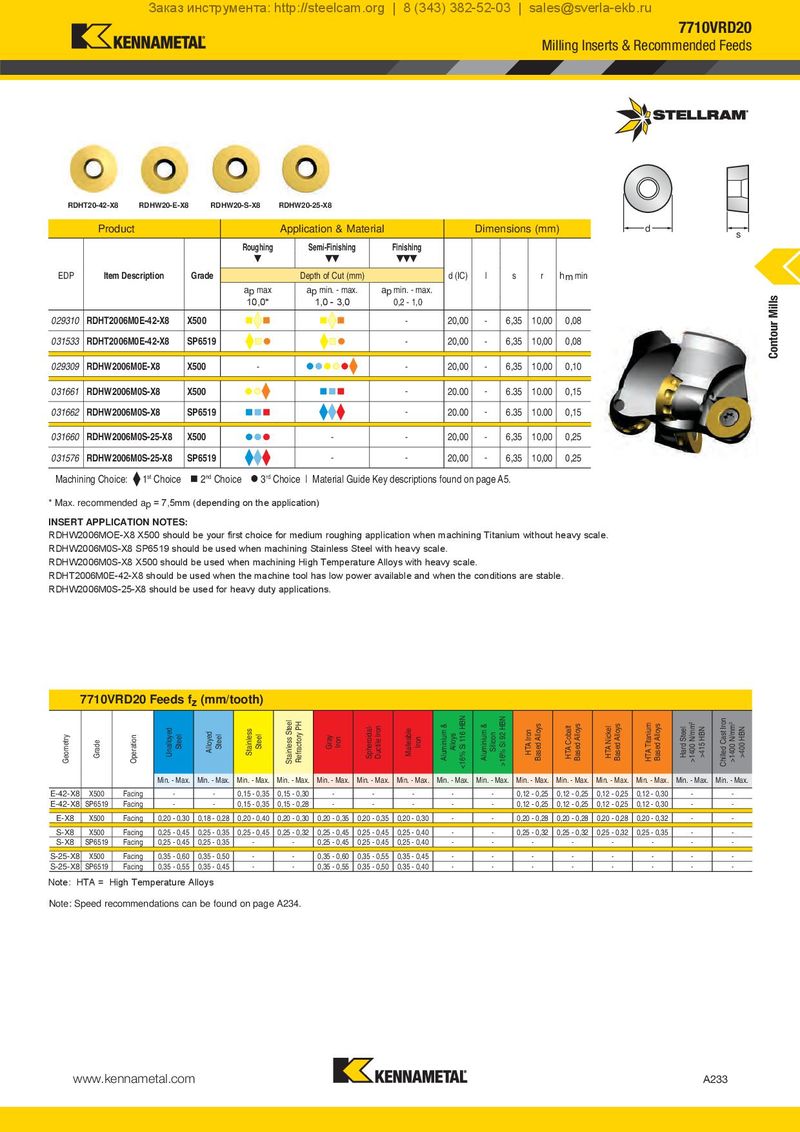

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 7710VRD20 Milling Inserts & Recommended Feeds RDHT20-42-X8 RDHW20-E-X8 RDHW20-S-X8 RDHW20-25-X8 Product Application & Material Dimensions (mm) d s Roughing Semi-Finishing Finishing EDP Item Description Grade Depth of Cut (mm) d (IC) l s r hm min ap max ap min. - max. ap min. - max. Contour Mills 10,0* 1,0 - 3,0 0,2 - 1,0 029310 RDHT2006M0E-42-X8 X500 - 20,00 - 6,35 10,00 0,08 031533 RDHT2006M0E-42-X8 SP6519 - 20,00 - 6,35 10,00 0,08 029309 RDHW2006M0E-X8 X500 - - 20,00 - 6,35 10,00 0,10 031661 RDHW2006M0S-X8 X500 - 20.00 - 6.35 10.00 0,15 031662 RDHW2006M0S-X8 SP6519 - 20.00 - 6.35 10.00 0,15 031660 RDHW2006M0S-25-X8 X500 - - 20,00 - 6,35 10,00 0,25 031576 RDHW2006M0S-25-X8 SP6519 - - 20,00 - 6,35 10,00 0,25 Machining Choice: 1st Choice 2nd Choice 3rd Choice | Material Guide Key descriptions found on page A5. * Max. recommended ap = 7,5mm (depending on the application) INSERT APPLICATION NOTES: RDHW2006MOE-X8 X500 should be your first choice for medium roughing application when machining Titanium without heavy scale. RDHW2006M0S-X8 SP6519 should be used when machining Stainless Steel with heavy scale. RDHW2006M0S-X8 X500 should be used when machining High Temperature Alloys with heavy scale. RDHT2006M0E-42-X8 should be used when the machine tool has low power available and when the conditions are stable. RDHW2006M0S-25-X8 should be used for heavy duty applications. 7710VRD20 Feeds fz (mm/tooth) Geometry Grade Operation Unalloyed Steel Alloyed Steel Stainless Steel Stainless Steel Refractory PH Gray Iron Spheroidal- Ductile Iron Malleable Iron Aluminium & Alloys <16% Si 116 HBN Aluminium & Silicon >16% Si 92 HBN HTA Iron Based Alloys HTA Cobalt Based Alloys HTA Nickel Based Alloys HTA Titanium Based Alloys Hard Steel >1400 N/mm2 >415 HBN Chilled Cast Iron >1400 N/mm2 >400 HBN Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. E-42-X8 X500 Facing - - 0,15 - 0,35 0,15 - 0,30 - - - - - 0,12 - 0,25 0,12 - 0,25 0,12 - 0,25 0,12 - 0,30 - - E-42-X8 SP6519 Facing - - 0,15 - 0,35 0,15 - 0,28 - - - - - 0,12 - 0,25 0,12 - 0,25 0,12 - 0,25 0,12 - 0,30 - - E-X8 X500 Facing 0,20 - 0,30 0,18 - 0,28 0,20 - 0,40 0,20 - 0,30 0,20 - 0,35 0,20 - 0,35 0,20 - 0,30 - - 0,20 - 0,28 0,20 - 0,28 0,20 - 0,28 0,20 - 0,32 - - S-X8 X500 Facing 0,25 - 0,45 0,25 - 0,35 0,25 - 0,45 0,25 - 0,32 0,25 - 0,45 0,25 - 0,45 0,25 - 0,40 - - 0,25 - 0,32 0,25 - 0,32 0,25 - 0,32 0,25 - 0,35 - - S-X8 SP6519 Facing 0,25 - 0,45 0,25 - 0,35 - - 0,25 - 0,45 0,25 - 0,45 0,25 - 0,40 - - - - - - - - S-25-X8 X500 Facing 0,35 - 0,60 0,35 - 0,50 - - 0,35 - 0,60 0,35 - 0,55 0,35 - 0,45 - - - - - - - - S-25-X8 SP6519 Facing 0,35 - 0,55 0,35 - 0,45 - - 0,35 - 0,55 0,35 - 0,50 0,35 - 0,40 - - - - - - - - Note: HTA = High Temperature Alloys Note: Speed recommendations can be found on page A234. www.kennametal.com A233

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы