Каталог Stellram фрез со сменными пластинами - страница 159

Навигация

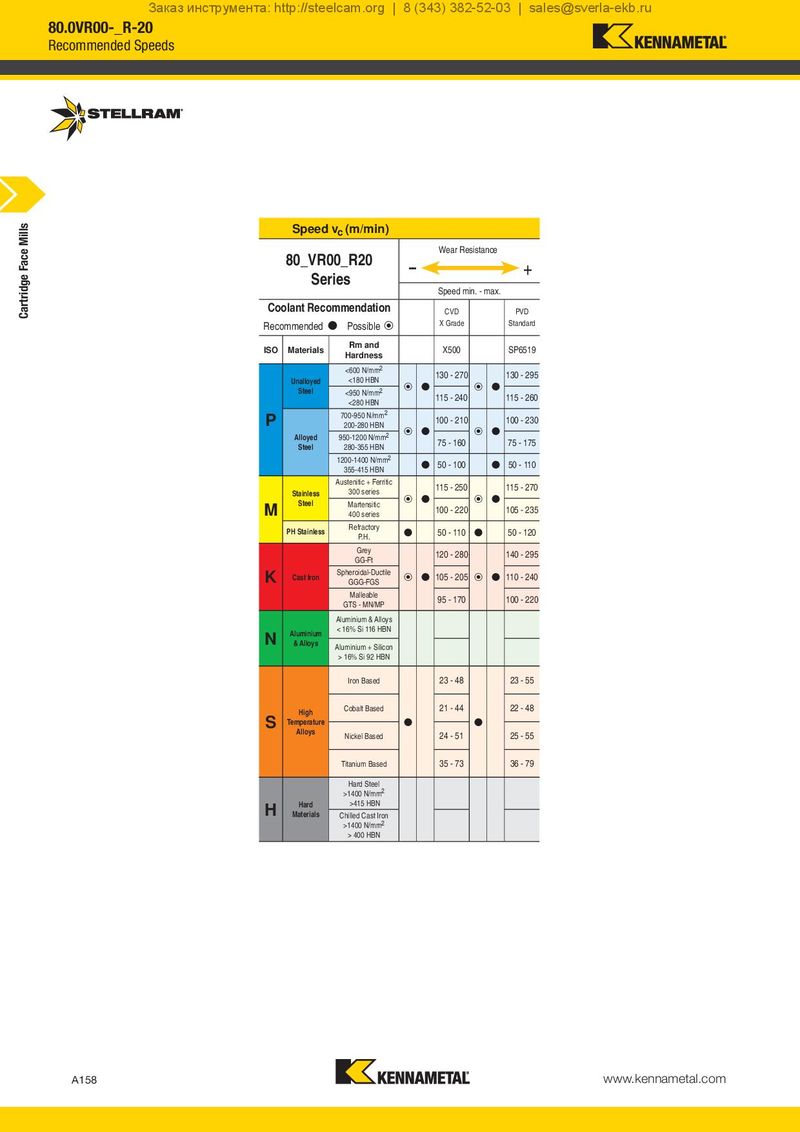

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 80.0VR00-_R-20 Recommended Speeds Cartridge Face Mills Speed vc (m/min) 80_VR00_R20 Wear Resistance Series -- + Speed min. - max. Coolant Recommendation CVD PVD Recommended Possible X Grade Standard ISO Materials Rm and X500 SP6519 Hardness <600 N/mm2 130 - 270 130 - 295 Unalloyed <180 HBN Steel <950 N/mm2 115 - 240 115 - 260 <280 HBN P 700-950 N/mm2 100 - 210 100 - 230 200-280 HBN Alloyed 950-1200 N/mm2 75 - 160 75 - 175 Steel 280-355 HBN 1200-1400 N/mm2 50 - 100 50 - 110 355-415 HBN Austenitic + Ferritic 115 - 250 115 - 270 Stainless 300 series M Steel Martensitic 100 - 220 105 - 235 400 series PH Stainless Refractory 50 - 110 50 - 120 P.H. Grey 120 - 280 140 - 295 GG-Ft K Cast Iron Spheroidal-Ductile 105 - 205 110 - 240 GGG-FGS Malleable 95 - 170 100 - 220 GTS - MN/MP Aluminium & Alloys N Aluminium < 16% Si 116 HBN & Alloys Aluminium + Silicon > 16% Si 92 HBN Iron Based 23 - 48 23 - 55 High Cobalt Based 21 - 44 22 - 48 S Temperature Alloys Nickel Based 24 - 51 25 - 55 Titanium Based 35 - 73 36 - 79 Hard Steel >1400 N/mm2 H Hard >415 HBN Materials Chilled Cast Iron >1400 N/mm2 > 400 HBN A158 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы