Каталог Stellram фрез со сменными пластинами - страница 146

Навигация

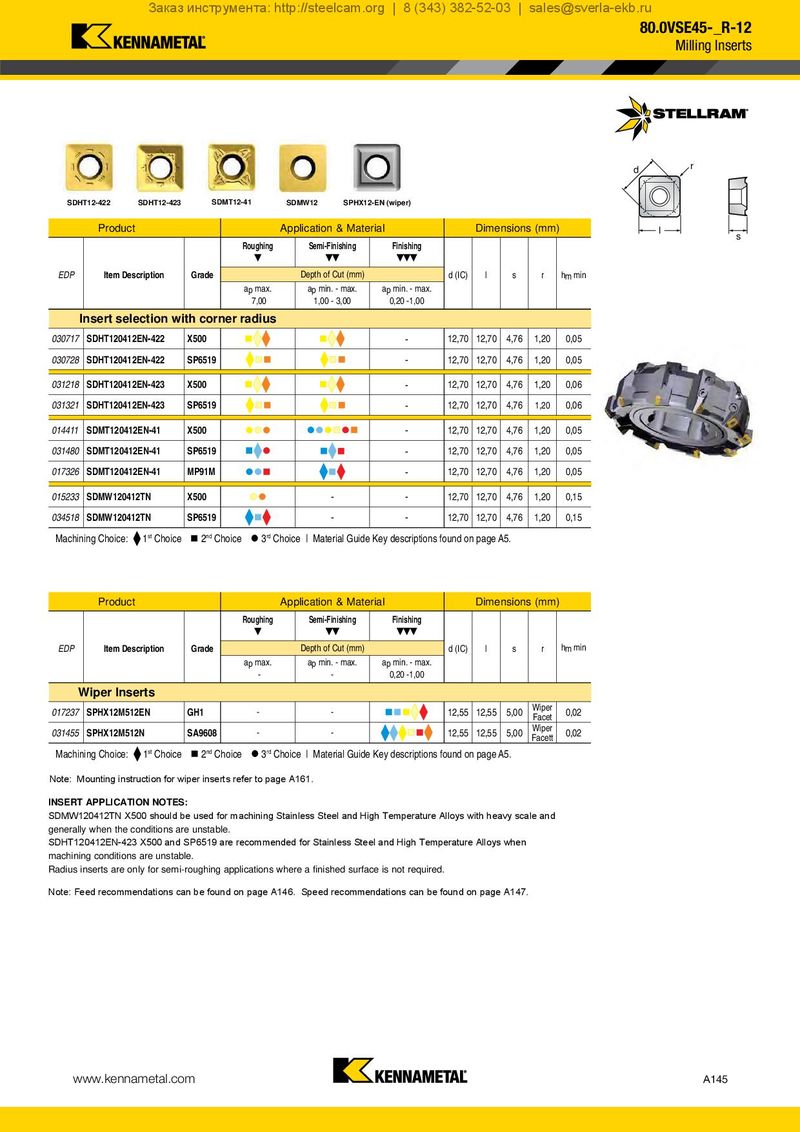

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 80.0VSE45-_R-12 Milling Inserts d r SDHT12-422 SDHT12-423 SDMT12-41 SDMW12 SPHX12-EN (wiper) Product Application & Material Dimensions (mm) l s Roughing Semi-Finishing Finishing EDP Item Description Grade Depth of Cut (mm) d (IC) l s r hm min ap max. ap min. - max. ap min. - max. 7,00 1,00 - 3,00 0,20 -1,00 Insert selection with corner radius 030717 SDHT120412EN-422 X500 - 12,70 12,70 4,76 1,20 0,05 030728 SDHT120412EN-422 SP6519 - 12,70 12,70 4,76 1,20 0,05 031218 SDHT120412EN-423 X500 - 12,70 12,70 4,76 1,20 0,06 031321 SDHT120412EN-423 SP6519 - 12,70 12,70 4,76 1,20 0,06 014411 SDMT120412EN-41 X500 - 12,70 12,70 4,76 1,20 0,05 031480 SDMT120412EN-41 SP6519 - 12,70 12,70 4,76 1,20 0,05 017326 SDMT120412EN-41 MP91M - 12,70 12,70 4,76 1,20 0,05 015233 SDMW120412TN X500 - - 12,70 12,70 4,76 1,20 0,15 034518 SDMW120412TN SP6519 - - 12,70 12,70 4,76 1,20 0,15 Machining Choice: 1st Choice 2nd Choice 3rd Choice | Material Guide Key descriptions found on page A5. Product Application & Material Dimensions (mm) Roughing Semi-Finishing Finishing EDP Item Description Grade Depth of Cut (mm) d (IC) l s r hm min ap max. ap min. - max. ap min. - max. - - 0,20 -1,00 Wiper Inserts 017237 SPHX12M512EN GH1 - - 12,55 12,55 5,00 Wiper 0,02 Facet 031455 SPHX12M512N SA9608 - - 12,55 12,55 5,00 Wiper 0,02 Facett Machining Choice: 1st Choice 2nd Choice 3rd Choice | Material Guide Key descriptions found on page A5. Note: Mounting instruction for wiper inserts refer to page A161. INSERT APPLICATION NOTES: SDMW120412TN X500 should be used for machining Stainless Steel and High Temperature Alloys with heavy scale and generally when the conditions are unstable. SDHT120412EN-423 X500 and SP6519 are recommended for Stainless Steel and High Temperature Alloys when machining conditions are unstable. Radius inserts are only for semi-roughing applications where a finished surface is not required. Note: Feed recommendations can be found on page A146. Speed recommendations can be found on page A147. www.kennametal.com A145

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы