Общий каталог SGS 2018 - страница 377

Навигация

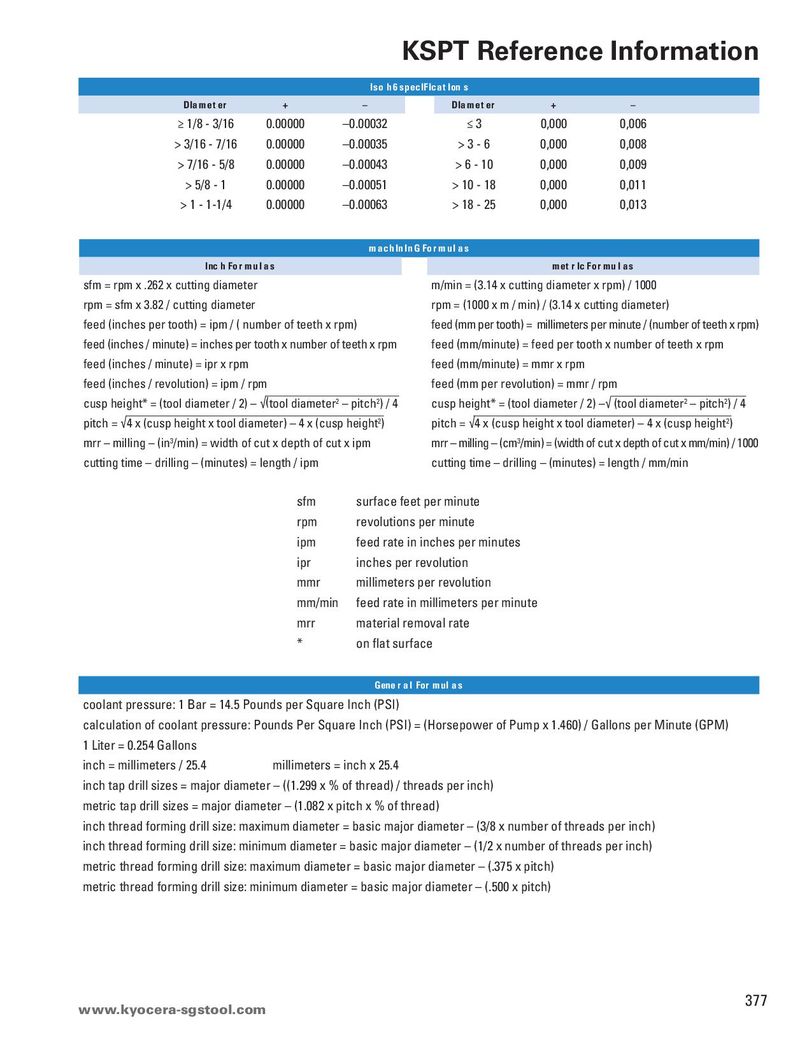

KSPT Reference Information ISO h 6 S pecificat ion s Dia m et er + – Dia m et er + – ≥ 1/8 - 3/16 0.00000 –0.00032 ≤3 0,000 0,006 > 3/16 - 7/16 0.00000 –0.00035 >3-6 0,000 0,008 > 7/16 - 5/8 0.00000 –0.00043 > 6 - 10 0,000 0,009 > 5/8 - 1 0.00000 –0.00051 > 10 - 18 0,000 0,011 > 1 - 1-1/4 0.00000 –0.00063 > 18 - 25 0,000 0,013 M a ch in in g Fo r m u l a s Inc h Fo r m u l a s M et r ic Fo r mu l a s sfm = rpm x .262 x cutting diameter m/min = (3.14 x cutting diameter x rpm) / 1000 rpm = sfm x 3.82 / cutting diameter rpm = (1000 x m / min) / (3.14 x cutting diameter) feed (inches per tooth) = ipm / ( number of teeth x rpm) feed (mm per tooth) = millimeters per minute / (number of teeth x rpm) feed (inches / minute) = inches per tooth x number of teeth x rpm feed (mm/minute) = feed per tooth x number of teeth x rpm feed (inches / minute) = ipr x rpm feed (mm/minute) = mmr x rpm feed (inches / revolution) = ipm / rpm feed (mm per revolution) = mmr / rpm cusp height* = (tool diameter / 2) – √(tool diameter2 – pitch2) / 4 cusp height* = (tool diameter / 2) –√ (tool diameter2 – pitch2) / 4 pitch = √4 x (cusp height x tool diameter) – 4 x (cusp height2) pitch = √4 x (cusp height x tool diameter) – 4 x (cusp height2) mrr – milling – (in3/min) = width of cut x depth of cut x ipm mrr – milling – (cm3/min) = (width of cut x depth of cut x mm/min) / 1000 cutting time – drilling – (minutes) = length / ipm cutting time – drilling – (minutes) = length / mm/min sfm surface feet per minute rpm revolutions per minute ipm feed rate in inches per minutes ipr inches per revolution mmr millimeters per revolution mm/min feed rate in millimeters per minute mrr material removal rate * on flat surface Gene r a l For m ul a s coolant pressure: 1 Bar = 14.5 Pounds per Square Inch (PSI) calculation of coolant pressure: Pounds Per Square Inch (PSI) = (Horsepower of Pump x 1.460) / Gallons per Minute (GPM) 1 Liter = 0.254 Gallons inch = millimeters / 25.4 millimeters = inch x 25.4 inch tap drill sizes = major diameter – ((1.299 x % of thread) / threads per inch) metric tap drill sizes = major diameter – (1.082 x pitch x % of thread) inch thread forming drill size: maximum diameter = basic major diameter – (3/8 x number of threads per inch) inch thread forming drill size: minimum diameter = basic major diameter – (1/2 x number of threads per inch) metric thread forming drill size: maximum diameter = basic major diameter – (.375 x pitch) metric thread forming drill size: minimum diameter = basic major diameter – (.500 x pitch) www.kyocera-sgstool.com 377

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском