Общий каталог SGS 2018 - страница 321

Навигация

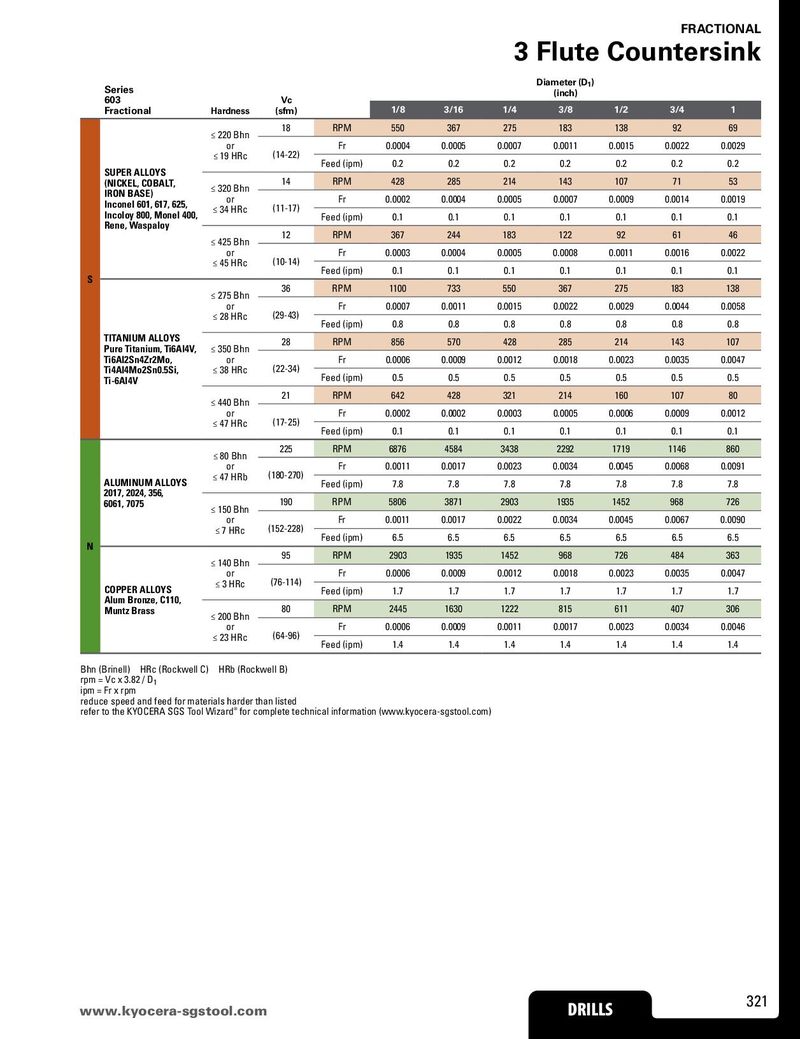

FRACTIONAL 3 Flute Countersink Series Diameter (D1) 603 Vc (inch) Fractional Hardness (sfm) 1/8 3/16 1/4 3/8 1/2 3/4 1 ≤ 220 Bhn 18 RPM 550 367 275 183 138 92 69 or (14-22) Fr 0.0004 0.0005 0.0007 0.0011 0.0015 0.0022 0.0029 ≤ 19 HRc Feed (ipm) 0.2 0.2 0.2 0.2 0.2 0.2 0.2 SUPER ALLOYS 14 RPM 428 285 214 143 107 71 53 (NICKEL, COBALT, ≤ 320 Bhn IRON BASE) or Fr 0.0002 0.0004 0.0005 0.0007 0.0009 0.0014 0.0019 Inconel 601, 617, 625, ≤ 34 HRc (11-17) Incoloy 800, Monel 400, Feed (ipm) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 Rene, Waspaloy 12 RPM 367 244 183 122 92 61 46 ≤ 425 Bhn or (10-14) Fr 0.0003 0.0004 0.0005 0.0008 0.0011 0.0016 0.0022 ≤ 45 HRc Feed (ipm) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 S 36 RPM 1100 733 550 367 275 183 138 ≤ 275 Bhn or (29-43) Fr 0.0007 0.0011 0.0015 0.0022 0.0029 0.0044 0.0058 ≤ 28 HRc Feed (ipm) 0.8 0.8 0.8 0.8 0.8 0.8 0.8 TITANIUM ALLOYS 28 RPM 856 570 428 285 214 143 107 Pure Titanium, Ti6Al4V, ≤ 350 Bhn Ti6Al2Sn4Zr2Mo, or (22-34) Fr 0.0006 0.0009 0.0012 0.0018 0.0023 0.0035 0.0047 Ti4Al4Mo2Sn0.5Si, ≤ 38 HRc Feed (ipm) 0.5 0.5 0.5 0.5 0.5 0.5 0.5 Ti-6Al4V ≤ 440 Bhn 21 RPM 642 428 321 214 160 107 80 or (17-25) Fr 0.0002 0.0002 0.0003 0.0005 0.0006 0.0009 0.0012 ≤ 47 HRc Feed (ipm) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 ≤ 80 Bhn 225 RPM 6876 4584 3438 2292 1719 1146 860 or (180-270) Fr 0.0011 0.0017 0.0023 0.0034 0.0045 0.0068 0.0091 ALUMINUM ALLOYS ≤ 47 HRb Feed (ipm) 7.8 7.8 7.8 7.8 7.8 7.8 7.8 2017, 2024, 356, 190 RPM 5806 3871 2903 1935 1452 968 726 6061, 7075 ≤ 150 Bhn or (152-228) Fr 0.0011 0.0017 0.0022 0.0034 0.0045 0.0067 0.0090 ≤ 7 HRc Feed (ipm) 6.5 6.5 6.5 6.5 6.5 6.5 6.5 N 95 RPM 2903 1935 1452 968 726 484 363 ≤ 140 Bhn or (76-114) Fr 0.0006 0.0009 0.0012 0.0018 0.0023 0.0035 0.0047 COPPER ALLOYS ≤ 3 HRc Feed (ipm) 1.7 1.7 1.7 1.7 1.7 1.7 1.7 Alum Bronze, C110, 80 RPM 2445 1630 1222 815 611 407 306 Muntz Brass ≤ 200 Bhn or (64-96) Fr 0.0006 0.0009 0.0011 0.0017 0.0023 0.0034 0.0046 ≤ 23 HRc Feed (ipm) 1.4 1.4 1.4 1.4 1.4 1.4 1.4 Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) rpm = Vc x 3.82 / D1 ipm = Fr x rpm reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyoceraD-sRgILsLtoSol.com DRILLS 321

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском