Общий каталог SGS 2018 - страница 309

Навигация

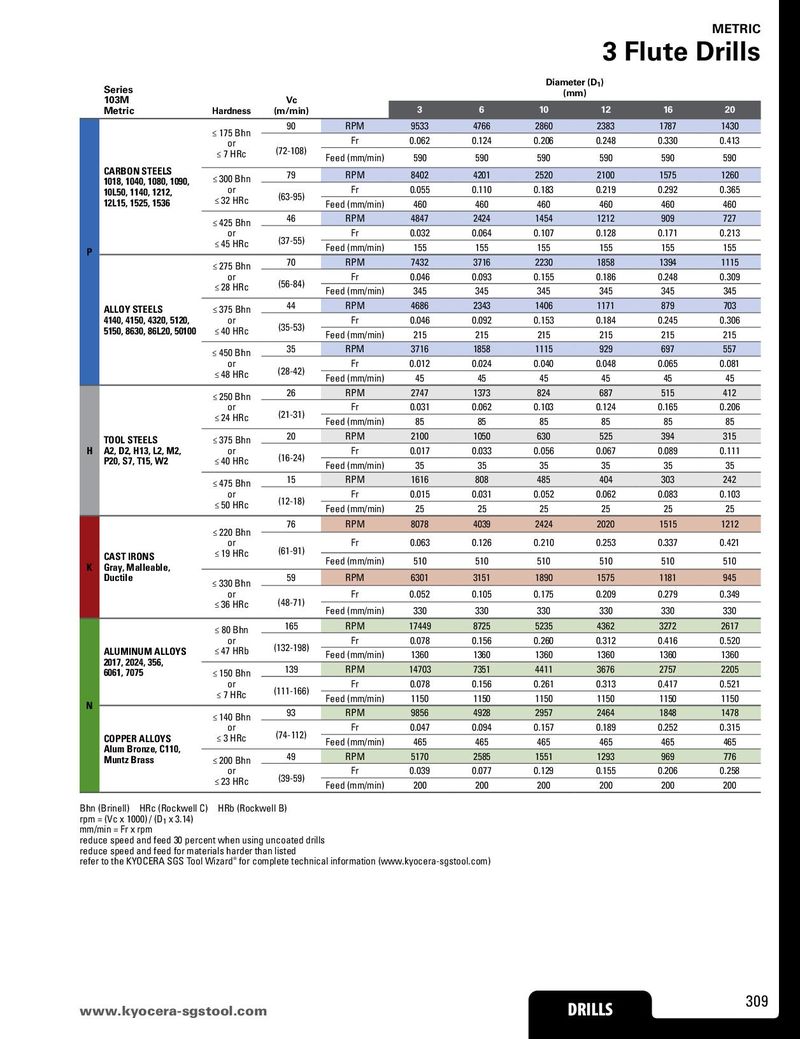

METRIC 3 Flute Drills Series Diameter (D1) 103M Vc (mm) Metric Hardness (m/min) 3 6 10 12 16 20 ≤ 175 Bhn 90 RPM 9533 4766 2860 2383 1787 1430 or Fr 0.062 0.124 0.206 0.248 0.330 0.413 ≤ 7 HRc (72-108) Feed (mm/min) 590 590 590 590 590 590 CARBON STEELS ≤ 300 Bhn 79 RPM 8402 4201 2520 2100 1575 1260 1018, 1040, 1080, 1090, or Fr 0.055 0.110 0.183 0.219 0.292 0.365 10L50, 1140, 1212, ≤ 32 HRc (63-95) 12L15, 1525, 1536 Feed (mm/min) 460 460 460 460 460 460 ≤ 425 Bhn 46 RPM 4847 2424 1454 1212 909 727 or (37-55) Fr 0.032 0.064 0.107 0.128 0.171 0.213 P ≤ 45 HRc Feed (mm/min) 155 155 155 155 155 155 ≤ 275 Bhn 70 RPM 7432 3716 2230 1858 1394 1115 or (56-84) Fr 0.046 0.093 0.155 0.186 0.248 0.309 ≤ 28 HRc Feed (mm/min) 345 345 345 345 345 345 ALLOY STEELS ≤ 375 Bhn 44 RPM 4686 2343 1406 1171 879 703 4140, 4150, 4320, 5120, or (35-53) Fr 0.046 0.092 0.153 0.184 0.245 0.306 5150, 8630, 86L20, 50100 ≤ 40 HRc Feed (mm/min) 215 215 215 215 215 215 ≤ 450 Bhn 35 RPM 3716 1858 1115 929 697 557 or (28-42) Fr 0.012 0.024 0.040 0.048 0.065 0.081 ≤ 48 HRc Feed (mm/min) 45 45 45 45 45 45 ≤ 250 Bhn 26 RPM 2747 1373 824 687 515 412 or (21-31) Fr 0.031 0.062 0.103 0.124 0.165 0.206 ≤ 24 HRc Feed (mm/min) 85 85 85 85 85 85 TOOL STEELS ≤ 375 Bhn 20 RPM 2100 1050 630 525 394 315 H A2, D2, H13, L2, M2, or (16-24) Fr 0.017 0.033 0.056 0.067 0.089 0.111 P20, S7, T15, W2 ≤ 40 HRc Feed (mm/min) 35 35 35 35 35 35 ≤ 475 Bhn 15 RPM 1616 808 485 404 303 242 or (12-18) Fr 0.015 0.031 0.052 0.062 0.083 0.103 ≤ 50 HRc Feed (mm/min) 25 25 25 25 25 25 ≤ 220 Bhn 76 RPM 8078 4039 2424 2020 1515 1212 or (61-91) Fr 0.063 0.126 0.210 0.253 0.337 0.421 CAST IRONS ≤ 19 HRc Feed (mm/min) 510 510 510 510 510 510 K Gray, Malleable, Ductile ≤ 330 Bhn 59 RPM 6301 3151 1890 1575 1181 945 or (48-71) Fr 0.052 0.105 0.175 0.209 0.279 0.349 ≤ 36 HRc Feed (mm/min) 330 330 330 330 330 330 ≤ 80 Bhn 165 RPM 17449 8725 5235 4362 3272 2617 or (132-198) Fr 0.078 0.156 0.260 0.312 0.416 0.520 ALUMINUM ALLOYS ≤ 47 HRb Feed (mm/min) 1360 1360 1360 1360 1360 1360 2017, 2024, 356, 139 RPM 14703 7351 4411 3676 2757 2205 6061, 7075 ≤ 150 Bhn or (111-166) Fr 0.078 0.156 0.261 0.313 0.417 0.521 ≤ 7 HRc Feed (mm/min) 1150 1150 1150 1150 1150 1150 N 93 RPM 9856 4928 2957 2464 1848 1478 ≤ 140 Bhn or (74-112) Fr 0.047 0.094 0.157 0.189 0.252 0.315 COPPER ALLOYS ≤ 3 HRc Feed (mm/min) 465 465 465 465 465 465 Alum Bronze, C110, 49 RPM 5170 2585 1551 1293 969 776 Muntz Brass ≤ 200 Bhn or (39-59) Fr 0.039 0.077 0.129 0.155 0.206 0.258 ≤ 23 HRc Feed (mm/min) 200 200 200 200 200 200 Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fr x rpm reduce speed and feed 30 percent when using uncoated drills reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyoceraD-sRgILsLtoSol.com DRILLS 309

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском