Общий каталог SGS 2018 - страница 274

Навигация

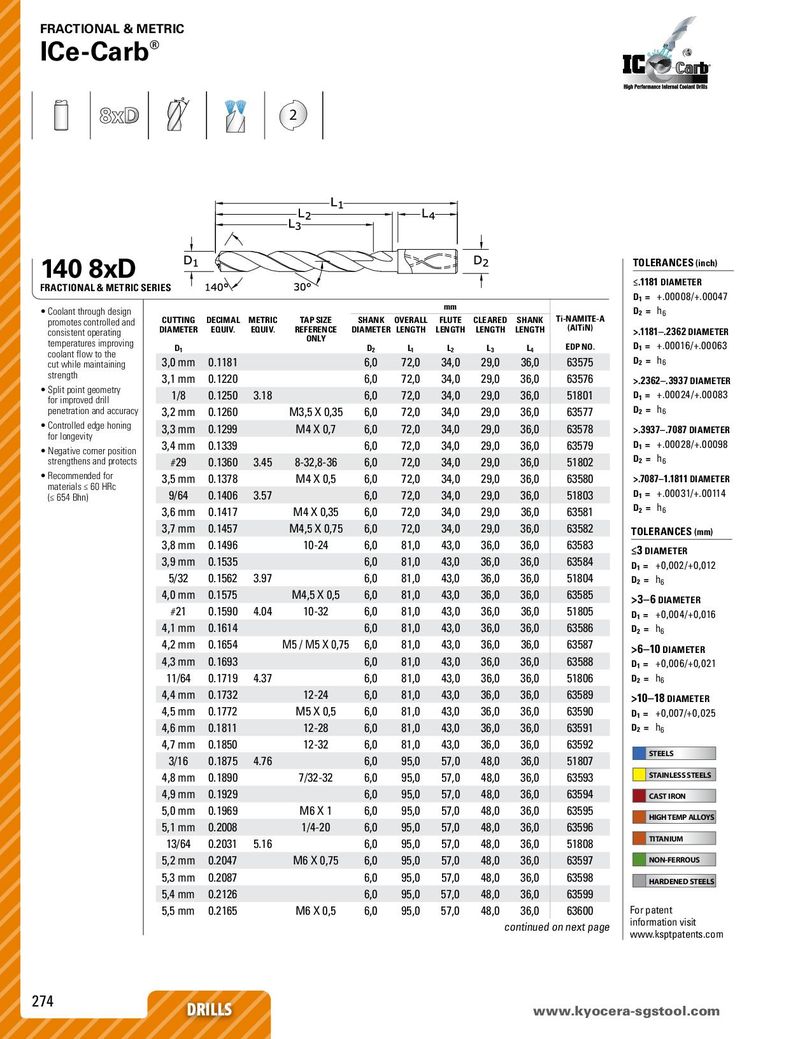

FRACTIONAL & METRIC ICe-Carb® ® 2 140 8xD TOLERANCES (inch) FRACTIONAL & METRIC SERIES ≤.1181 DIAMETER D1 = +.00008/+.00047 • Coolant through design mm D2 = h6 promotes controlled and CUTTING DECIMAL METRIC TAP SIZE SHANK OVERALL FLUTE CLEARED SHANK Ti-NAMITE-A consistent operating DIAMETER EQUIV. EQUIV. REFERENCE DIAMETER LENGTH LENGTH LENGTH LENGTH (AlTiN) >.1181–.2362 DIAMETER temperatures improving ONLY EDP NO. D1 = +.00016/+.00063 coolant flow to the D1 D2 L1 L2 L3 L4 cut while maintaining 3,0 mm 0.1181 6,0 72,0 34,0 29,0 36,0 63575 D2 = h6 strength 3,1 mm 0.1220 6,0 72,0 34,0 29,0 36,0 63576 >.2362–.3937 DIAMETER • Split point geometry 1/8 0.1250 3.18 6,0 72,0 34,0 29,0 36,0 51801 D1 = +.00024/+.00083 for improved drill h6 penetration and accuracy 3,2 mm 0.1260 M3,5 X 0,35 6,0 72,0 34,0 29,0 36,0 63577 D2 = • Controlled edge honing 3,3 mm 0.1299 M4 X 0,7 6,0 72,0 34,0 29,0 36,0 63578 >.3937–.7087 DIAMETER for longevity 3,4 mm 0.1339 6,0 72,0 34,0 29,0 36,0 63579 D1 = +.00028/+.00098 • Negative corner position D2 = h6 strengthens and protects #29 0.1360 3.45 8-32,8-36 6,0 72,0 34,0 29,0 36,0 51802 • Recommended for 3,5 mm 0.1378 M4 X 0,5 6,0 72,0 34,0 29,0 36,0 63580 >.7087–1.1811 DIAMETER materials ≤ 60 HRc 9/64 0.1406 3.57 6,0 72,0 34,0 29,0 36,0 51803 D1 = +.00031/+.00114 (≤ 654 Bhn) 3,6 mm 0.1417 M4 X 0,35 6,0 72,0 34,0 29,0 36,0 63581 D2 = h6 3,7 mm 0.1457 M4,5 X 0,75 6,0 72,0 34,0 29,0 36,0 63582 TOLERANCES (mm) 3,8 mm 0.1496 10-24 6,0 81,0 43,0 36,0 36,0 63583 ≤3 DIAMETER 3,9 mm 0.1535 6,0 81,0 43,0 36,0 36,0 63584 D1 = + 0, 0 0 2 /+ 0, 012 5/32 0.1562 3.97 6,0 81,0 43,0 36,0 36,0 51804 D2 = h6 4,0 mm 0.1575 M4,5 X 0,5 6,0 81,0 43,0 36,0 36,0 63585 >3–6 DIAMETER #21 0.1590 4.04 10-32 6,0 81,0 43,0 36,0 36,0 51805 D1 = +0,004/+0,016 4,1 mm 0.1614 6,0 81,0 43,0 36,0 36,0 63586 D2 = h6 4,2 mm 0.1654 M5 / M5 X 0,75 6,0 81,0 43,0 36,0 36,0 63587 >6–10 DIAMETER 4,3 mm 0.1693 6,0 81,0 43,0 36,0 36,0 63588 D1 = +0,006/+0,021 11/64 0.1719 4.37 6,0 81,0 43,0 36,0 36,0 51806 D2 = h6 4,4 mm 0.1732 12-24 6,0 81,0 43,0 36,0 36,0 63589 >10–18 DIAMETER 4,5 mm 0.1772 M5 X 0,5 6,0 81,0 43,0 36,0 36,0 63590 D1 = +0,007/+0,025 4,6 mm 0.1811 12-28 6,0 81,0 43,0 36,0 36,0 63591 D2 = h6 4,7 mm 0.1850 12-32 6,0 81,0 43,0 36,0 36,0 63592 3/16 0.1875 4.76 6,0 95,0 57,0 48,0 36,0 51807 STEELS 4,8 mm 0.1890 7/32-32 6,0 95,0 57,0 48,0 36,0 63593 STAINLESS STEELS 4,9 mm 0.1929 6,0 95,0 57,0 48,0 36,0 63594 CAST IRON 5,0 mm 0.1969 M6 X 1 6,0 95,0 57,0 48,0 36,0 63595 HIGH TEMP ALLOYS 5,1 mm 0.2008 1/4-20 6,0 95,0 57,0 48,0 36,0 63596 13/64 0.2031 5.16 6,0 95,0 57,0 48,0 36,0 51808 TITANIUM 5,2 mm 0.2047 M6 X 0,75 6,0 95,0 57,0 48,0 36,0 63597 NON-FERROUS 5,3 mm 0.2087 6,0 95,0 57,0 48,0 36,0 63598 HARDENED STEELS 5,4 mm 0.2126 6,0 95,0 57,0 48,0 36,0 63599 5,5 mm 0.2165 M6 X 0,5 6,0 95,0 57,0 48,0 36,0 63600 For patent continued on next page information visit www.ksptpatents.com 274 DRILLS www.kDyRoIcLeLrSa-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском